SMT siv cov pa roj hmab muab tshuaj txhuam cov cua reflow vuam kab noj hniav tsom xam thiab kev daws teeb meem (2023 Essence Edition), koj tsim nyog nws!

1 Kev Taw Qhia

Nyob rau hauv lub rooj sib txoos hauv Circuit Court, solder paste yog luam tawm rau ntawm lub rooj tsav xwm Circuit Court board ua ntej, thiab tom qab ntawd ntau yam khoom siv hluav taws xob tau affixed. Thaum kawg, tom qab lub reflow rauv, cov tin hlaws nyob rau hauv lub solder paste yog melted thiab tag nrho cov hom ntawm hluav taws xob Cheebtsam thiab solder ncoo ntawm lub Circuit Court board yog welded ua ke kom paub qhov sib dhos ntawm hluav taws xob submodules. surfacemounttechnology (sMT) yog nce siv nyob rau hauv high-density ntim khoom, xws li system qib pob (siP), ballgridarray (BGA) li, thiab lub hwj chim liab qab Chip, square tiaj tus pin-tsawg pob (quad aatNo-lead, hu ua QFN) ntaus ntawv.

Vim yog cov yam ntxwv ntawm cov txheej txheem vuam thiab cov khoom siv, tom qab rov ua cov vuam ntawm cov khoom siv loj loj no, yuav muaj qhov nyob hauv thaj chaw vuam, uas yuav cuam tshuam rau cov khoom siv hluav taws xob, thermal zog thiab cov khoom siv tshuab ua haujlwm, thiab txawm tias ua rau cov khoom tsis ua haujlwm, yog li ntawd, txhawm rau txhim kho cov khoom siv hlau nplaum reflow vuam kab noj hniav tau dhau los ua cov txheej txheem thiab cov teeb meem kev lag luam uas yuav tsum tau daws cov khoom lag luam, thiab cov khoom lag luam yuav tsum tau daws. kab noj hniav, thiab muab kev txhim kho cov kev daws teeb meem, cov pa roj hmab paste reflow vuam txheej txheem vuam cheeb tsam ntawm QFN ntau dua 10mm2 los yog vuam cheeb tsam ntau dua 6 mm2 lub liab qab nti daws yog tsis muaj.

Siv Preformsolder vuam thiab lub tshuab nqus tsev reflux rauv vuam los txhim kho qhov vuam. Prefabricated solder xav tau cov cuab yeej tshwj xeeb los taw tes flux. Piv txwv li, lub nti yog offset thiab tilted tiag tom qab lub nti muab tso ncaj qha rau ntawm lub prefabricated solder. Yog hais tias lub flux mount nti yog reflow thiab ces taw tes, cov txheej txheem yog nce los ntawm ob reflow, thiab tus nqi ntawm prefabricated solder thiab flux cov ntaub ntawv yog ntau dua li solder paste.

Cov khoom siv nqus tsev vacuum yog kim dua, lub tshuab nqus tsev muaj peev xwm ntawm lub tshuab nqus tsev ywj pheej yog tsawg heev, tus nqi ua haujlwm tsis siab, thiab qhov teeb meem tin splashing yog qhov tseem ceeb, uas yog ib qho tseem ceeb hauv kev siv cov khoom siv high-density thiab me-pitch. Nyob rau hauv daim ntawv no, raws li cov txheej txheem ntawm cov pa welding paste reflow welding txheej txheem, ib tug tshiab thib ob reflow welding txheej txheem yog tsim thiab qhia los txhim kho lub vuam kab noj hniav thiab daws cov teeb meem ntawm kev sib txuas thiab yas foob tawg los ntawm vuam kab noj hniav.

2 Solder paste printing reflow vuam kab noj hniav thiab ntau lawm mechanism

2.1 Vuam kab noj hniav

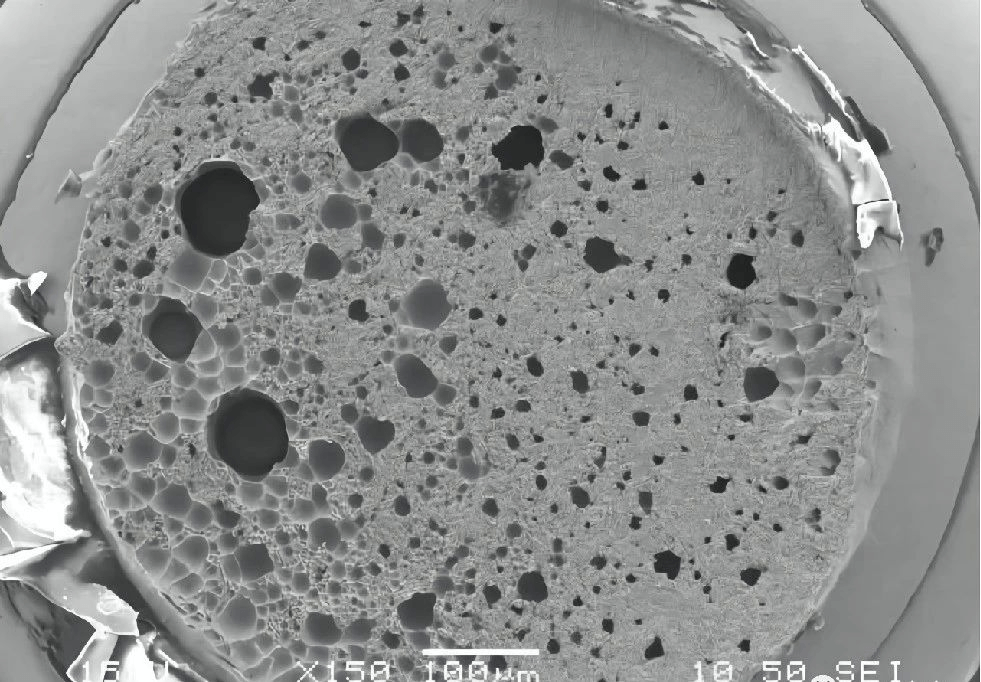

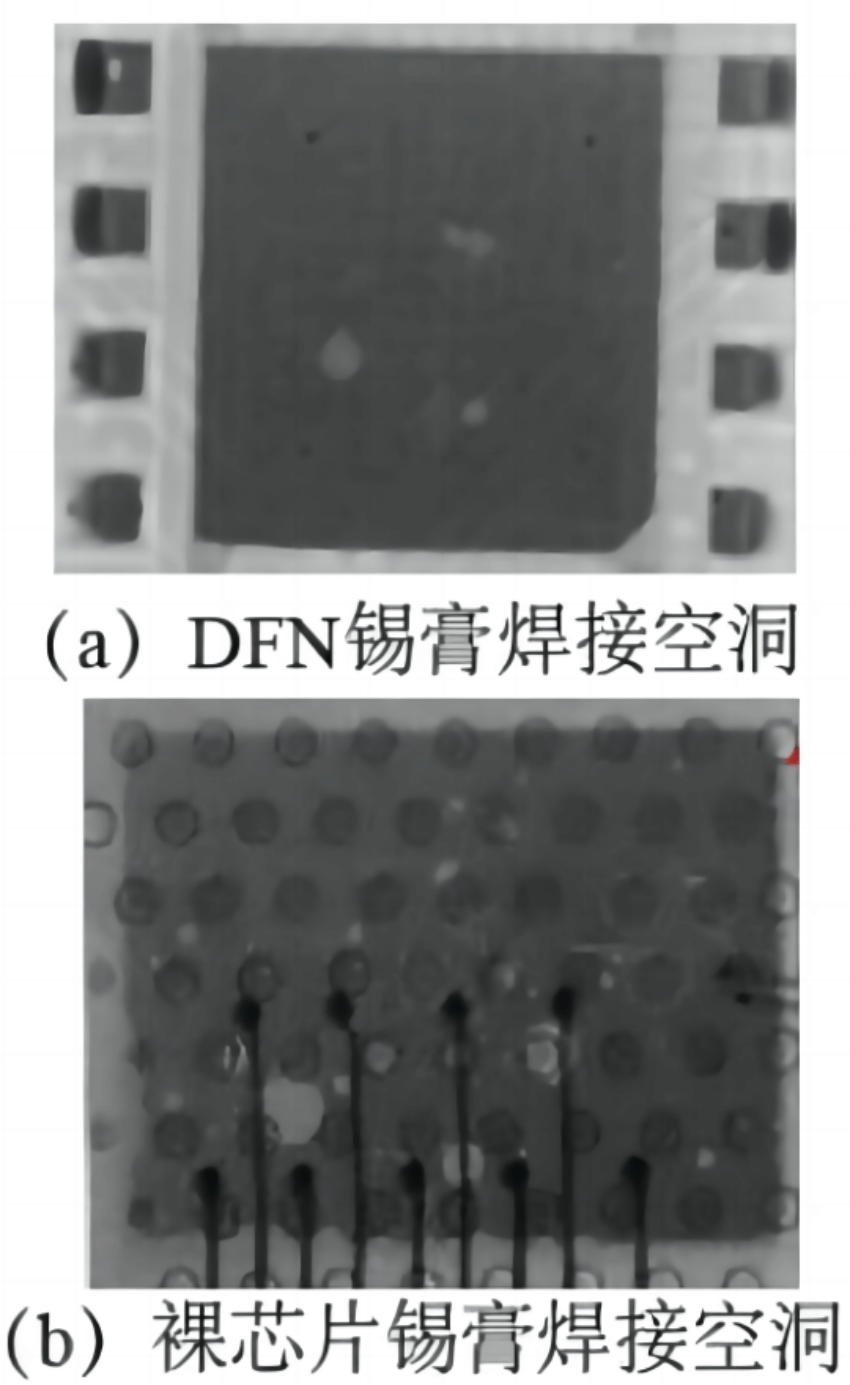

Tom qab reflow vuam, cov khoom raug kuaj hauv x-ray. Cov qhov nyob hauv thaj chaw vuam nrog cov xim sib dua tau pom tias yog vim tsis muaj cov khoom siv hauv vuam txheej, raws li qhia hauv daim duab 1

X-ray nrhiav pom ntawm lub qhov npuas

2.2 Tsim mechanism ntawm vuam kab noj hniav

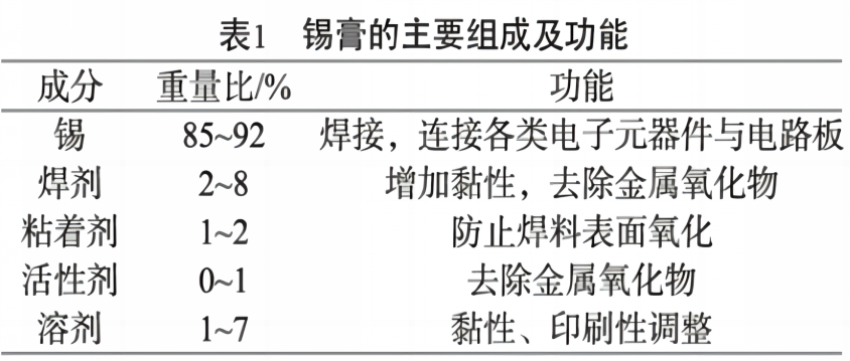

Noj sAC305 solder paste ua piv txwv, lub ntsiab muaj pes tsawg leeg thiab kev ua haujlwm tau pom nyob rau hauv Table 1. Cov hlaws thiab cov hlaws tin yog sib koom ua ke hauv cov duab paste. Qhov hnyav piv ntawm tin solder rau flux yog li 9: 1, thiab qhov ntim piv yog li 1: 1.

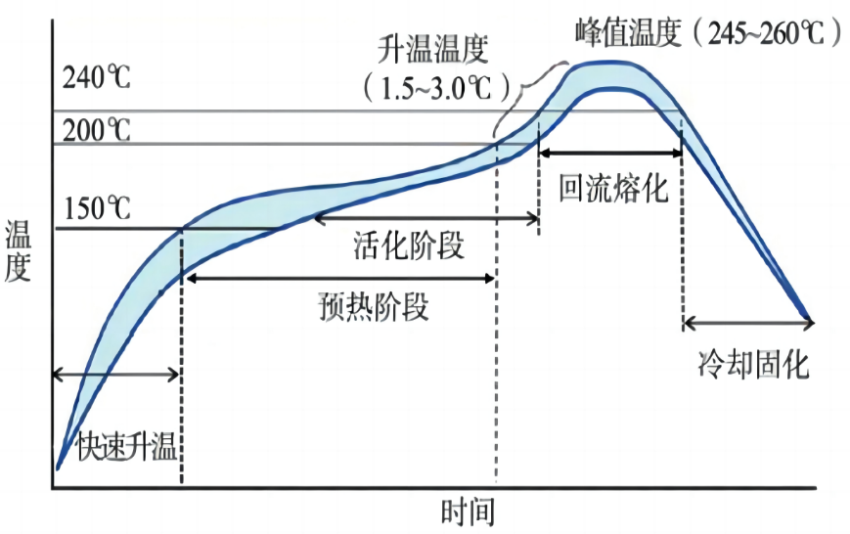

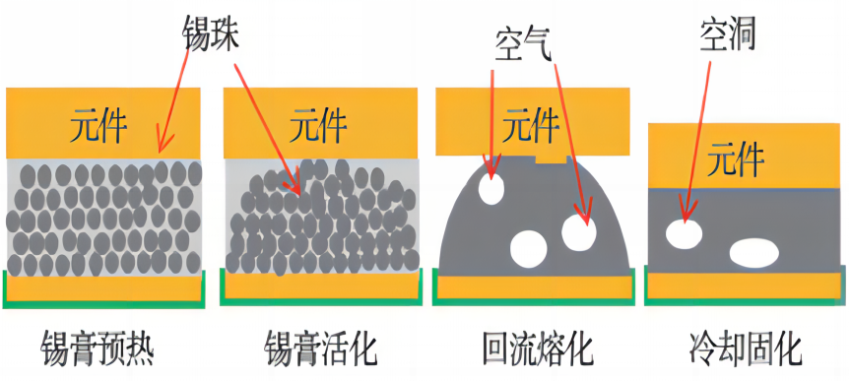

Tom qab cov tshuaj nplaum tau luam tawm thiab txuas nrog ntau yam khoom siv hluav taws xob, cov tshuaj txhuam hniav yuav raug plaub theem ntawm preheating, ua kom, reflux thiab txias thaum nws dhau los ntawm lub qhov cub reflux. Lub xeev ntawm cov tshuaj txhuam hniav kuj txawv nrog qhov sib txawv ntawm qhov sib txawv ntawm cov theem sib txawv, raws li pom hauv daim duab 2.

Profile siv rau txhua qhov chaw ntawm reflow soldering

Nyob rau hauv lub preheating thiab activation theem, cov volatile Cheebtsam nyob rau hauv lub flux nyob rau hauv lub solder paste yuav volatilized rau hauv roj thaum rhuab. Nyob rau tib lub sijhawm, cov pa roj carbon monoxide yuav raug tsim tawm thaum cov oxide ntawm cov txheej vuam raug tshem tawm. Qee qhov ntawm cov pa roj no yuav volatilize thiab tawm hauv cov tshuaj txhuam hniav, thiab cov hlaws hlaws yuav nruj nreem kaw vim qhov volatilization ntawm flux. Nyob rau hauv lub reflux theem, cov seem flux nyob rau hauv lub solder paste yuav evaporate sai sai, cov tin hlaws yuav yaj, ib tug me me ntawm flux volatile gas thiab feem ntau ntawm cov huab cua ntawm cov tin hlaws yuav tsis dispersed nyob rau hauv lub sij hawm, thiab cov seem nyob rau hauv lub molten tin thiab nyob rau hauv lub nro ntawm lub molten tin yog hamburger sandwich vaj huam sib luag thiab pads raug muag. nyob rau hauv cov kua tin yog qhov nyuaj rau kev khiav tawm tsuas yog los ntawm upward buoyancy Lub sij hawm melting sab sauv yog luv heev. Thaum cov molten tin txias thiab dhau los ua cov khoom tin, qhov pores tshwm nyob rau hauv cov txheej txheem vuam thiab cov qhov sib txuas tau tsim, raws li qhia hauv daim duab 3.

Schematic daim duab ntawm void generated los ntawm solder paste reflow vuam

Lub hauv paus ua rau ntawm vuam kab noj hniav yog tias cov pa los yog cov pa tsis muaj zog uas qhwv hauv cov tshuaj txhuam tom qab melting tsis tiav tag. Cov yam ntxwv cuam tshuam muaj xws li cov khoom siv tshuaj pleev xim, cov khoom siv tshuaj pleev xim rau cov ntawv luam tawm, cov khoom siv luam ntawv luam tawm, qhov kub thiab txias, reflux lub sij hawm, vuam loj, qauv thiab lwm yam.

3. Kev txheeb xyuas qhov cuam tshuam ntawm cov khoom siv hluav taws xob luam tawm reflow vuam qhov

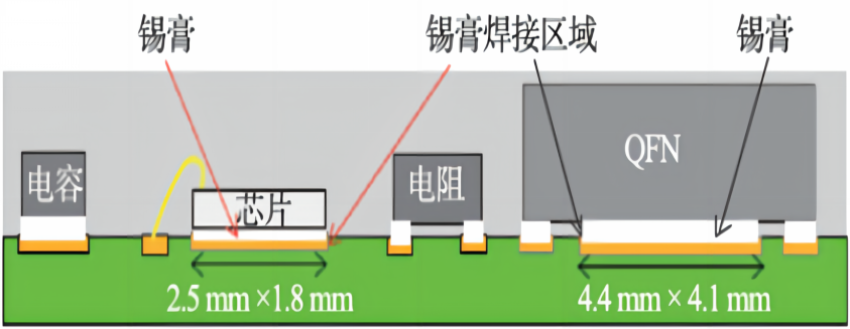

QFN thiab liab qab kev ntsuam xyuas tau siv los xyuas kom meej tias lub ntsiab ua rau reflow vuam voids, thiab nrhiav txoj hauv kev los txhim kho cov reflow vuam voids luam tawm los ntawm solder paste. QFN thiab liab qab nti solder paste reflow vuam khoom profile yog qhia nyob rau hauv daim duab 4, QFN vuam nto loj yog 4.4mmx4.1mm, vuam nto yog tinned txheej (100% ntshiab tin); Qhov vuam loj ntawm cov nti liab qab yog 3.0mmx2.3mm, txheej vuam yog sputtered npib tsib xee-vanadium bimetallic txheej, thiab txheej txheej yog vanadium. Lub vuam ncoo ntawm lub substrate yog electroless nickel-palladium kub-dipping, thiab lub thickness yog 0.4μm / 0.06μm / 0.04μm. SAC305 solder paste yog siv, cov khoom siv hluav taws xob luam tawm yog DEK Horizon APix, cov khoom siv hluav taws xob rov qab yog BTUPyramax150N, thiab cov khoom siv x-ray yog DAGExD7500VR.

QFN thiab liab qab nti vuam kos duab

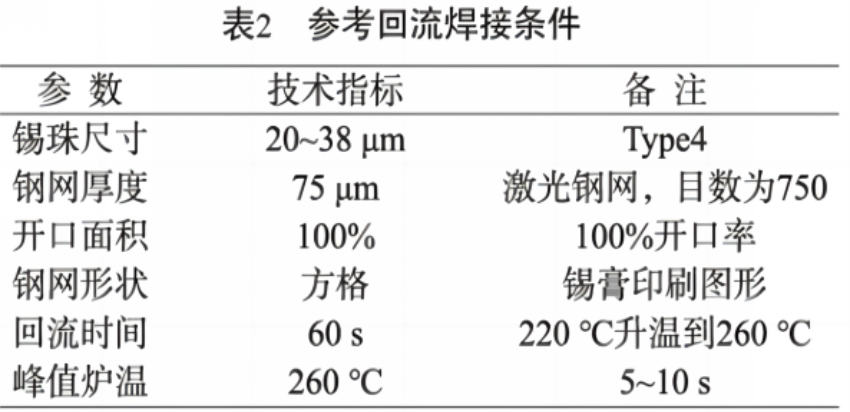

Txhawm rau pab txhawb kev sib piv ntawm cov txiaj ntsig kev xeem, reflow vuam tau ua raws li cov xwm txheej hauv Table 2.

Reflow welding condition table

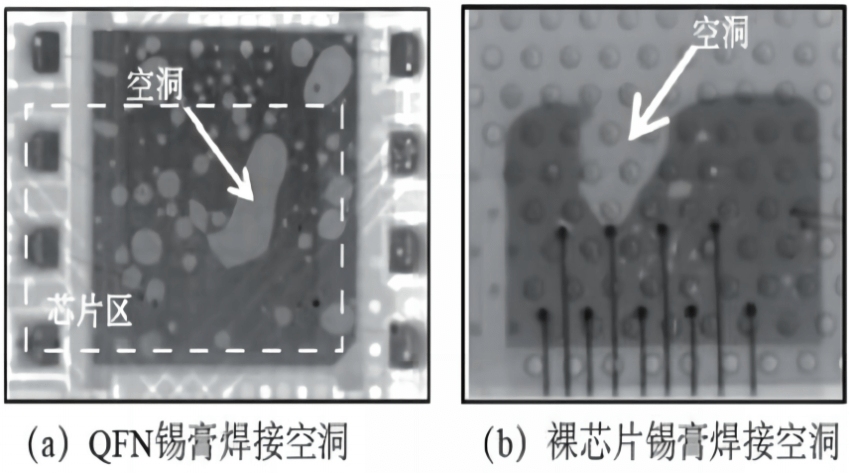

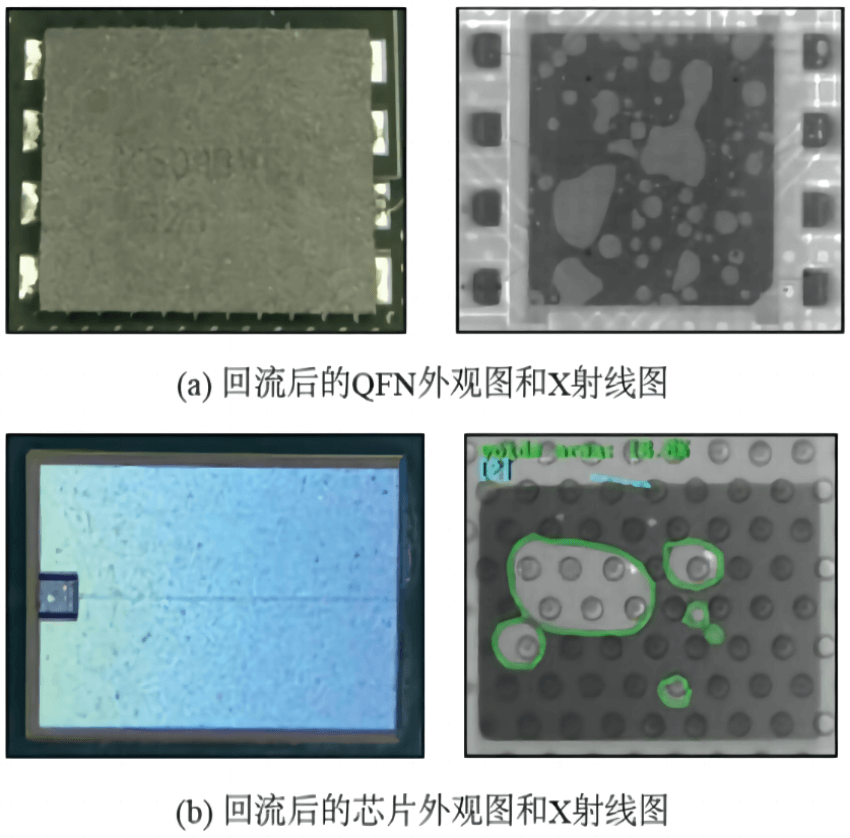

Tom qab qhov chaw mounting thiab reflow welding tiav lawm, lub vuam txheej tau kuaj pom los ntawm X-ray, thiab nws tau pom tias muaj qhov loj hauv cov vuam txheej hauv qab ntawm QFN thiab liab qab nti, raws li qhia hauv daim duab 5.

QFN thiab Chip Hologram (X-ray)

Txij li thaum tin hlaws loj, steel mesh thickness, qhib cheeb tsam tus nqi, steel mesh zoo, reflux lub sij hawm thiab ncov lub qhov cub kub yuav tag nrho cov cuam tshuam rau reflow vuam voids, muaj ntau yam cuam tshuam, uas yuav raug txheeb xyuas ncaj qha los ntawm DOE xeem, thiab tus naj npawb ntawm kev sim pab pawg yuav loj heev. Nws yog ib qho tsim nyog yuav tsum tau soj ntsuam sai thiab txiav txim siab qhov tseem ceeb cuam tshuam los ntawm kev sib piv kev sib piv, thiab tom qab ntawd ua kom zoo dua qhov tseem ceeb cuam tshuam los ntawm DOE.

3.1 Dimensions ntawm solder qhov thiab solder paste tin hlaws

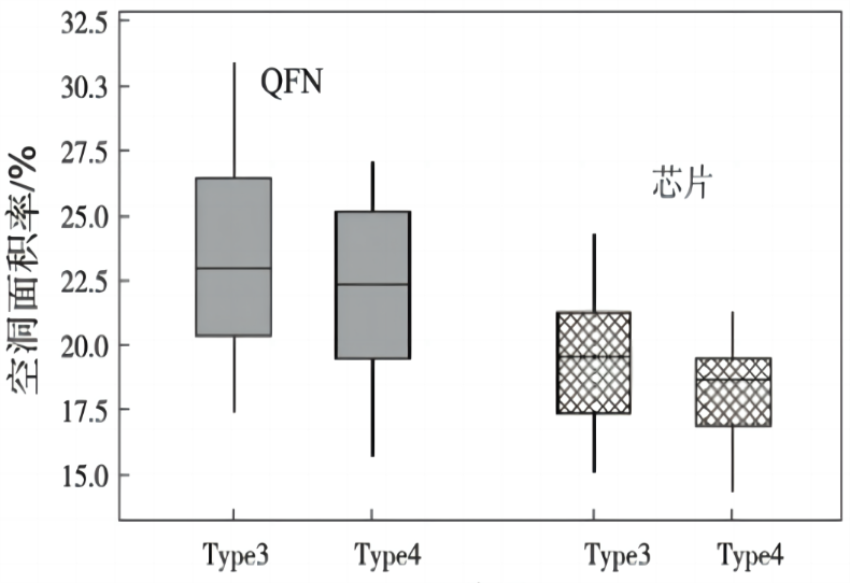

Nrog type3 (bead loj 25-45 μm) SAC305 solder paste test, lwm yam kev mob tseem tsis hloov. Tom qab reflow, lub qhov nyob rau hauv lub solder txheej yog ntsuas thiab muab piv nrog type4 solder paste. Nws pom tau hais tias cov qhov nyob rau hauv cov txheej solder tsis sib txawv ntawm ob hom solder paste, qhia tau hais tias lub solder paste nrog txawv hlaws loj tsis muaj kev cuam tshuam rau lub qhov nyob rau hauv lub solder txheej, uas tsis yog ib qho tseem ceeb influencing, raws li qhia nyob rau hauv FIG. 6 Raws li qhia.

Kev sib piv ntawm cov xim hlau tin hmoov qhov nrog ntau qhov sib txawv

3.2 Thickness ntawm vuam kab noj hniav thiab luam ntawv hlau mesh

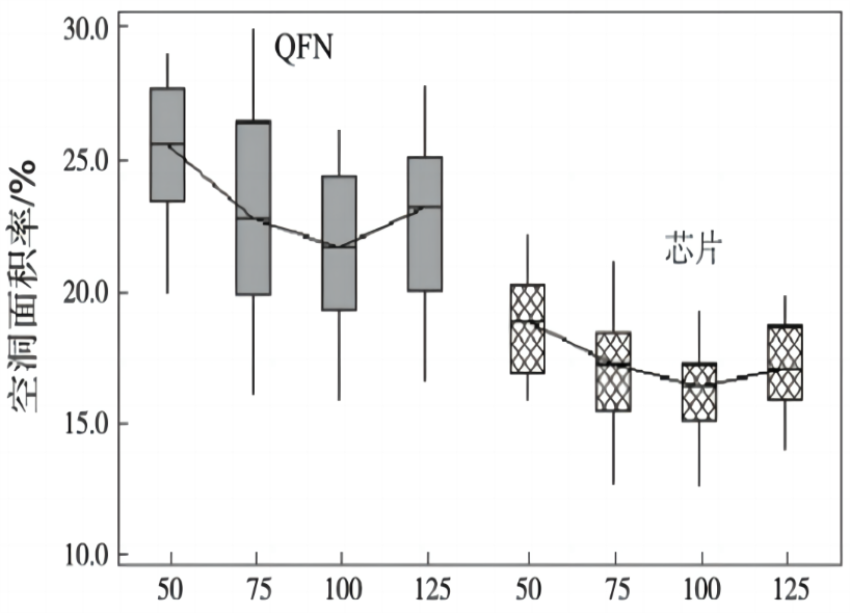

Tom qab reflow, cov kab noj hniav ntawm cov txheej welded tau ntsuas nrog cov ntawv luam tawm steel mesh nrog lub thickness ntawm 50 μm, 100 μm thiab 125 μm, thiab lwm yam kev mob tseem tsis hloov. Nws tau pom tias cov nyhuv ntawm cov thickness sib txawv ntawm cov hlau mesh (solder paste) ntawm QFN tau muab piv nrog cov ntawv luam tawm steel mesh nrog lub thickness ntawm 75 μm Raws li cov thickness ntawm cov hlau mesh nce, cov kab noj hniav cheeb tsam maj mam txo qis. Tom qab ncav cuag ib lub thickness (100μm), cov kab noj hniav cheeb tsam yuav thim rov qab thiab pib nce nrog qhov nce ntawm cov thickness ntawm cov hlau mesh, raws li qhia hauv daim duab 7.

Qhov no qhia tau hais tias thaum tus nqi ntawm cov muab tshuaj txhuam yog nce, cov kua tin nrog reflux yog npog los ntawm nti, thiab lub qhov hluav taws xob ntawm cov seem cua khiav tawm tsuas yog nqaim ntawm plaub sab. Thaum tus nqi ntawm cov tshuaj txhuam tau hloov pauv, qhov hluav taws xob ntawm cov pa tawm ntawm cov khoom seem tseem nce ntxiv, thiab cov cua tawg tam sim ntawd qhwv hauv cov kua tin los yog cov pa roj uas tsis muaj hluav taws xob khiav tawm cov kua tin yuav ua rau cov kua tin tuaj yeem tawg ntawm QFN thiab cov nti.

Qhov kev ntsuam xyuas pom tau tias nrog kev nce ntawm cov tuab ntawm cov hlau mesh, cov npuas tawg tshwm sim los ntawm kev khiav tawm ntawm huab cua lossis cov pa tsis haum yuav nce ntxiv, thiab qhov tshwm sim ntawm tin splashing nyob ib ncig ntawm QFN thiab nti yuav nce ntxiv.

Kev sib piv ntawm qhov nyob rau hauv steel mesh ntawm txawv thickness

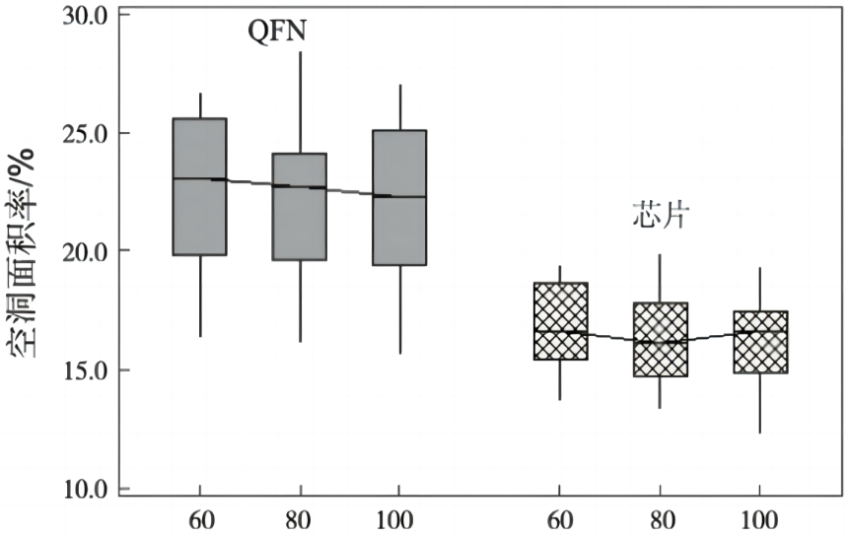

3.3 Thaj tsam piv ntawm vuam kab noj hniav thiab steel mesh qhib

Cov luam ntawv hlau mesh nrog qhov qhib ntawm 100%, 90% thiab 80% raug kuaj, thiab lwm yam kev mob tseem tsis hloov. Tom qab reflow, kab noj hniav cheeb tsam ntawm welded txheej yog ntsuas thiab muab piv nrog cov luam ntawv hlau mesh nrog 100% qhib tus nqi. Nws tau pom tias tsis muaj qhov sib txawv tseem ceeb hauv cov kab noj hniav ntawm cov txheej txheem welded raws li cov xwm txheej ntawm qhov qhib ntawm 100% thiab 90% 80%, raws li qhia hauv daim duab 8.

Cavity sib piv ntawm qhov sib txawv qhib cheeb tsam ntawm txawv steel mesh

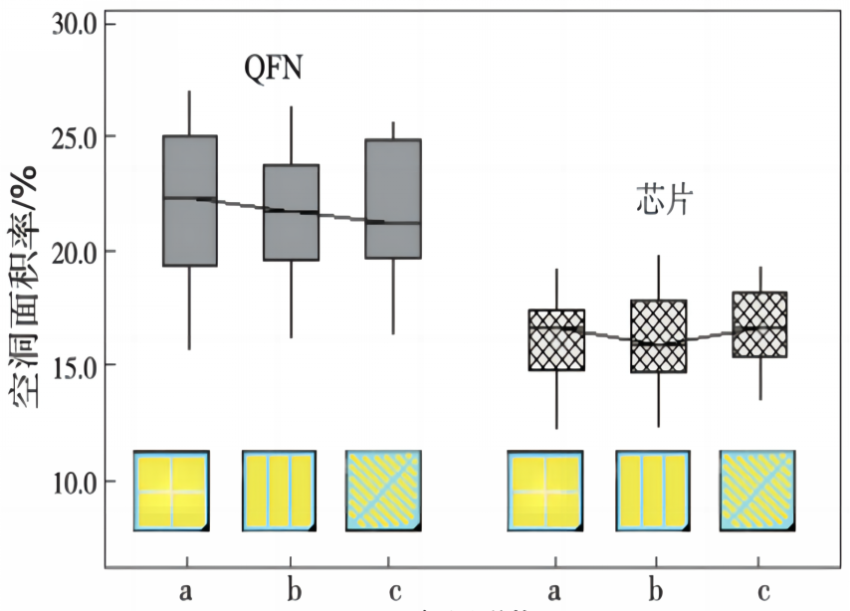

3.4 Welded kab noj hniav thiab luam ntawv hlau mesh zoo

Nrog rau kev ntsuam xyuas cov duab ntawm cov nplaum nplaum ntawm kab b thiab inclined grid c, lwm yam kev mob tseem tsis hloov. Tom qab reflow, kab noj hniav cheeb tsam ntawm lub vuam txheej yog ntsuas thiab muab piv nrog cov ntawv luam ntawm daim phiaj a. Nws pom tias tsis muaj qhov sib txawv tseem ceeb hauv cov kab noj hniav ntawm cov txheej txheem vuam nyob rau hauv cov xwm txheej ntawm daim phiaj, sawb thiab inclined daim phiaj, raws li qhia hauv daim duab 9.

Kev sib piv ntawm qhov nyob rau hauv txawv qhib hom ntawm steel mesh

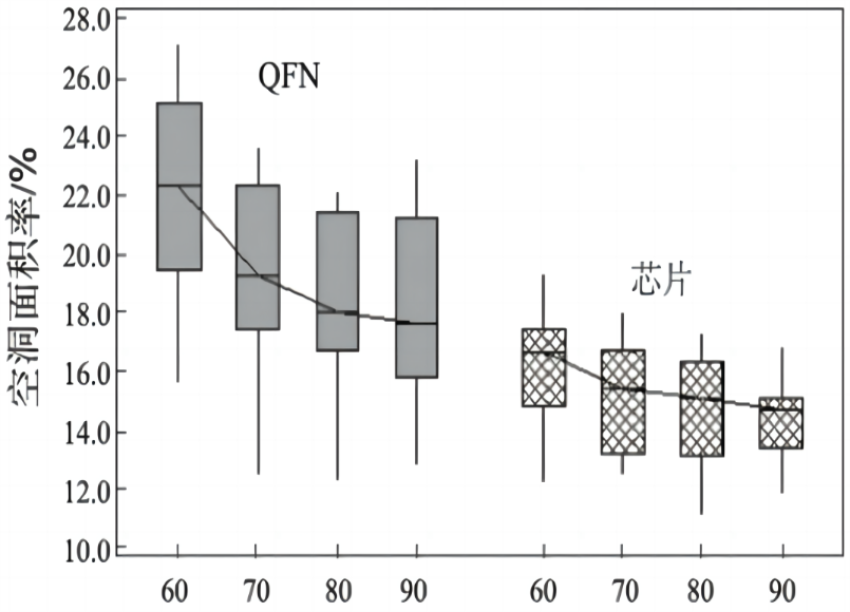

3.5 Vuam kab noj hniav thiab reflux lub sij hawm

Tom qab lub sij hawm reflux ntev (70 s, 80 s, 90 s) kev sim, lwm yam kev mob tseem tsis hloov, lub qhov nyob rau hauv lub vuam txheej tau ntsuas tom qab reflux, thiab piv nrog rau lub sij hawm reflux ntawm 60 s, nws tau pom tias nrog rau lub sij hawm reflux nce, qhov vuam qhov cheeb tsam txo, tab sis lub sij hawm maj mam txo, thiab lub sij hawm reflux tshwm sim. 10. Qhov no qhia tau hais tias nyob rau hauv cov ntaub ntawv ntawm lub sij hawm reflux tsis txaus, nce lub sij hawm reflux yog conducive mus rau tag nrho cov overflow ntawm cov huab cua qhwv nyob rau hauv molten kua tin, tab sis tom qab lub sij hawm reflux nce mus rau ib lub sij hawm, cov huab cua qhwv nyob rau hauv cov kua tin yog ib qho nyuaj rau overflow dua. Lub sij hawm reflux yog ib qho ntawm cov teeb meem cuam tshuam rau lub vuam kab noj hniav.

Kev sib piv ntawm qhov sib txawv reflux lub sij hawm ntev

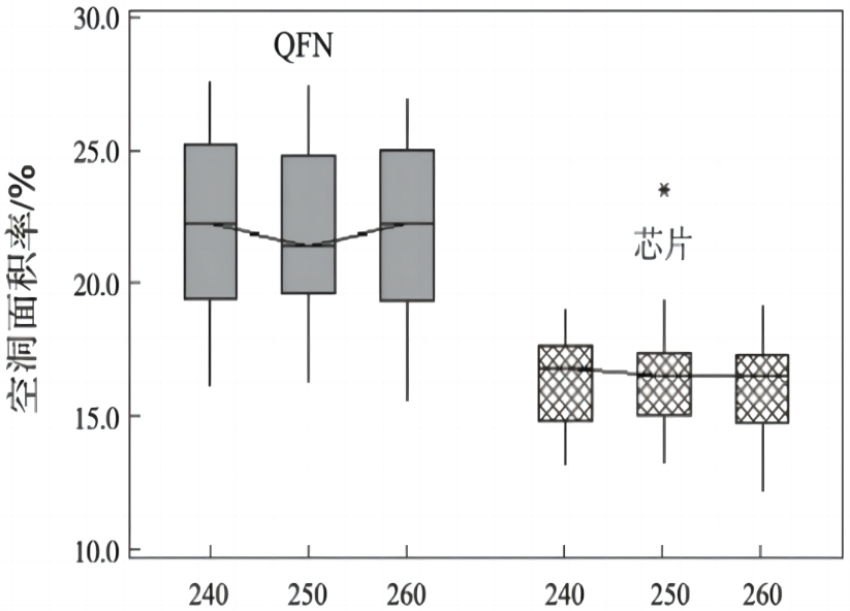

3.6 Vuam kab noj hniav thiab qhov siab tshaj qhov cub kub

Nrog 240 ℃ thiab 250 ℃ ncov rauv ntsuas kub thiab lwm yam kev hloov pauv tsis hloov, qhov chaw kab noj hniav ntawm cov txheej welded tau ntsuas tom qab rov qab, thiab piv nrog 260 ℃ ncov rauv kub, nws tau pom tias nyob rau hauv qhov sib txawv ncov rauv kub kub, kab noj hniav ntawm welded txheej ntawm QFN thiab nti tsis hloov pauv qhov sib txawv ntawm peak 1, raws li qhia tau hais tias qhov kub thiab txias. tsis muaj kev cuam tshuam rau QFN thiab lub qhov nyob rau hauv cov txheej txheem vuam ntawm cov nti, uas tsis yog qhov cuam tshuam.

Tsis muaj qhov sib piv ntawm qhov sib txawv ntawm qhov siab tshaj

Cov kev ntsuam xyuas saum toj no qhia tau hais tias cov yam tseem ceeb cuam tshuam rau lub vuam txheej kab noj hniav ntawm QFN thiab nti yog reflux lub sij hawm thiab steel mesh thickness.

4 Solder paste luam ntawv reflow vuam kab noj hniav txhim kho

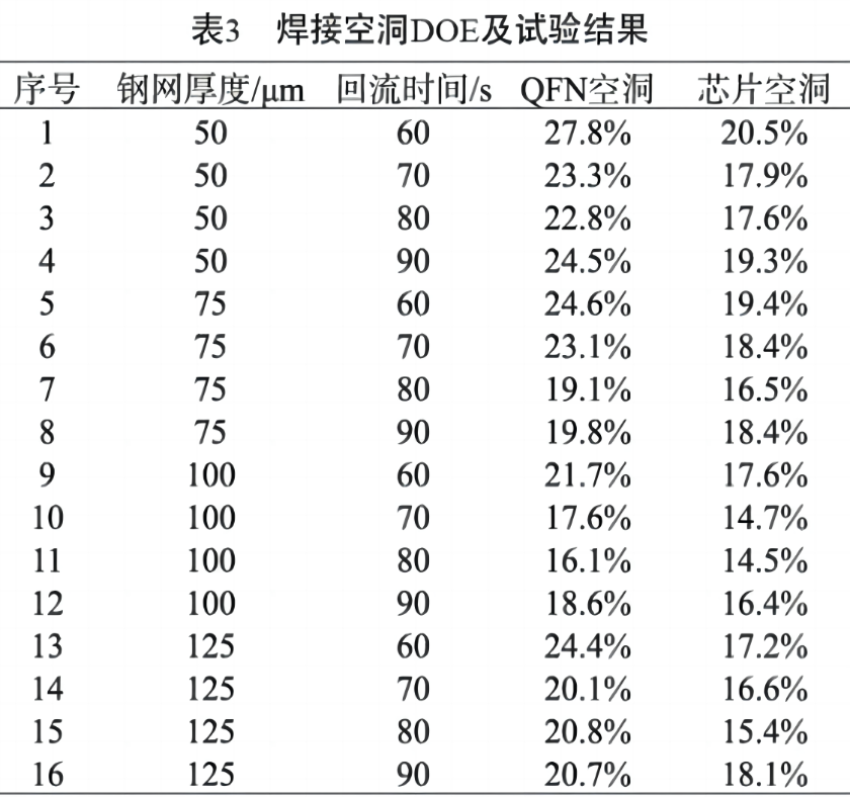

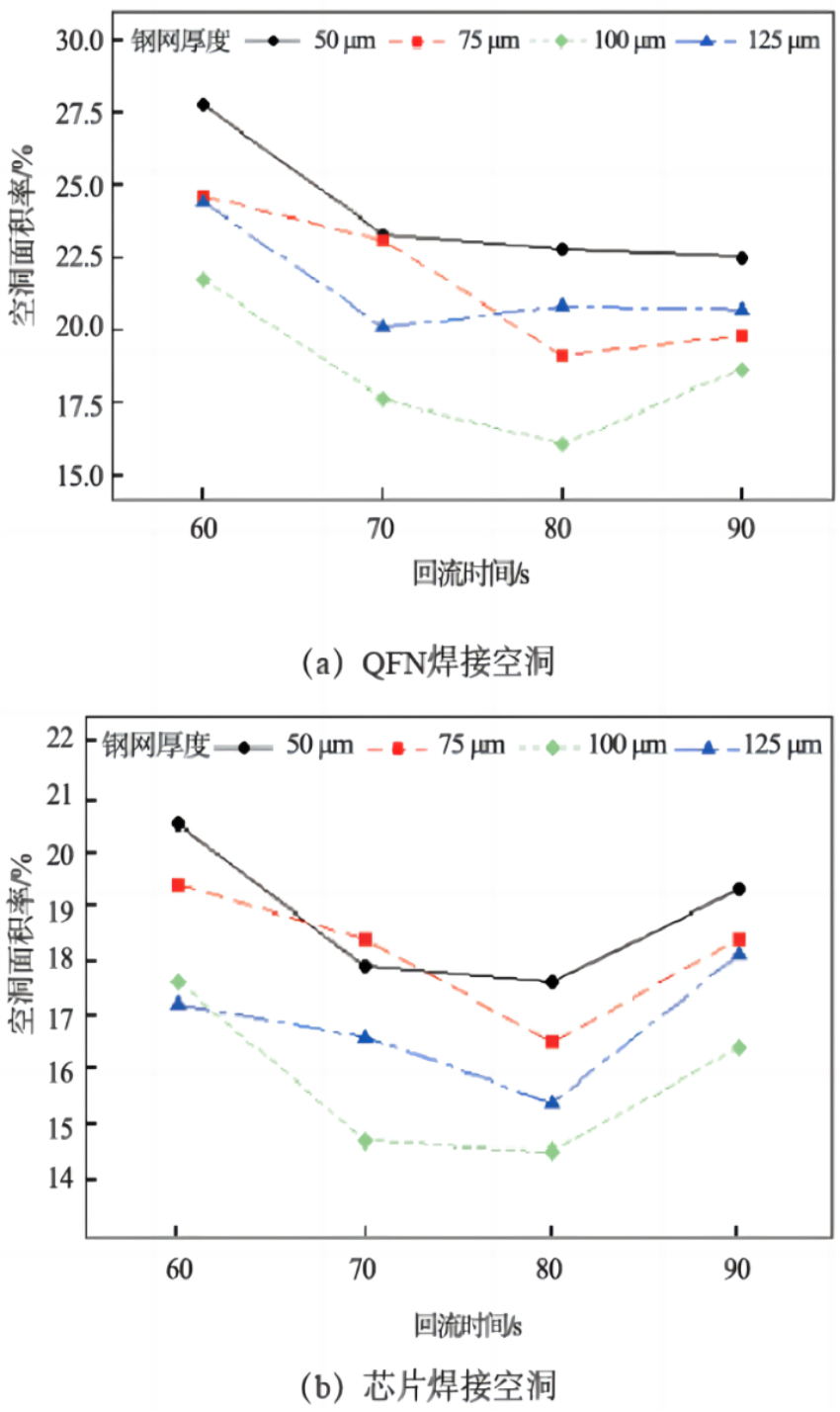

4.1 DOE xeem los txhim kho vuam kab noj hniav

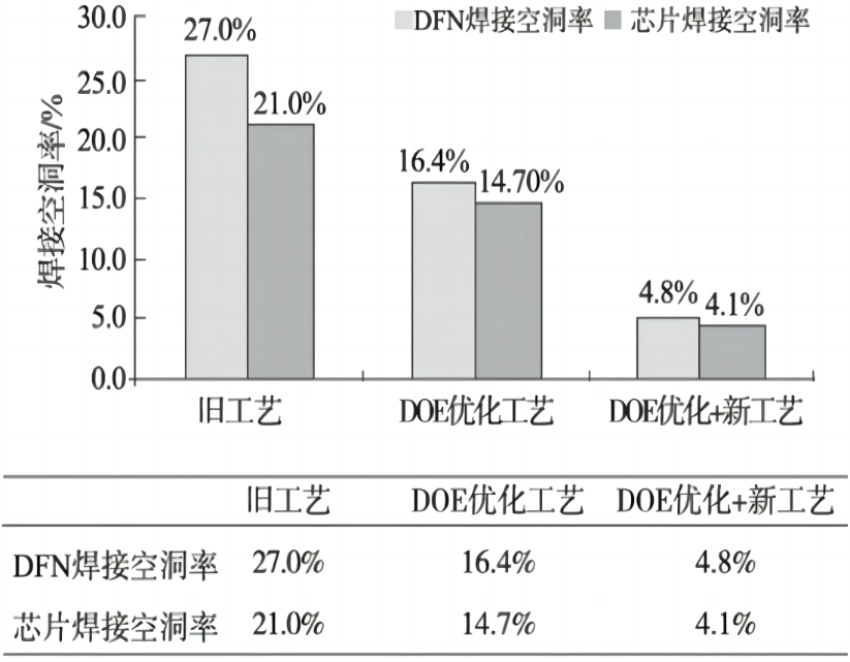

Lub qhov nyob rau hauv lub vuam txheej ntawm QFN thiab nti tau txhim kho los ntawm kev nrhiav pom tus nqi ntawm lub ntsiab cuam tshuam (reflux lub sij hawm thiab steel mesh thickness). Cov tshuaj txhuam hniav yog SAC305 type4, cov hlau mesh zoo yog hom kab sib chaws (100% qhib degree), qhov siab tshaj plaws rauv kub yog 260 ℃, thiab lwm yam kev sim ntsuas yog tib yam li cov khoom siv kuaj. DOE xeem thiab cov txiaj ntsig tau pom nyob rau hauv Table 3. Qhov cuam tshuam ntawm steel mesh thickness thiab reflux lub sij hawm ntawm QFN thiab nti welding qhov yog qhia nyob rau hauv daim duab 12. Los ntawm kev sib cuam tshuam kev tsom xam ntawm lub ntsiab influencing yam, Nws pom tau hais tias siv 100 μm steel mesh thickness thiab 80 s reflux lub sij hawm yuav txo tau lub Vuam nti kab noj hniav. Qhov vuam kab noj hniav ntawm QFN yog txo los ntawm qhov siab tshaj plaws 27.8% mus rau 16.1%, thiab qhov vuam kab noj hniav ntawm nti yog txo los ntawm qhov siab tshaj 20.5% mus rau 14.5%.

Hauv kev sim, 1000 cov khoom tau tsim nyob rau hauv qhov kev pom zoo (100 μm steel mesh thickness, 80 s reflux lub sij hawm), thiab vuam kab noj hniav tus nqi ntawm 100 QFN thiab nti tau random ntsuas. Qhov nruab nrab vuam kab noj hniav tus nqi ntawm QFN yog 16.4%, thiab qhov nruab nrab vuam kab noj hniav tus nqi ntawm nti yog 14.7% Qhov vuam kab noj hniav tus nqi ntawm cov nti thiab cov nti yog pom tseeb txo.

4.2 Cov txheej txheem tshiab txhim kho qhov vuam kab noj hniav

Qhov xwm txheej tsim khoom tiag tiag thiab kev sim qhia tau hais tias thaum qhov chaw vuam kab noj hniav hauv qab ntawm cov nti yog tsawg dua 10%, lub nti kab noj hniav txoj hauj lwm tawg teeb meem yuav tsis tshwm sim thaum lub sij hawm sib txuas thiab molding. Cov txheej txheem tsis zoo los ntawm DOE tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm kev tshuaj xyuas thiab kev daws cov qhov hauv cov khoom siv sib xyaw ua ke reflow vuam, thiab qhov vuam kab noj hniav thaj tsam ntawm cov nti yuav tsum tau txo qis ntxiv.

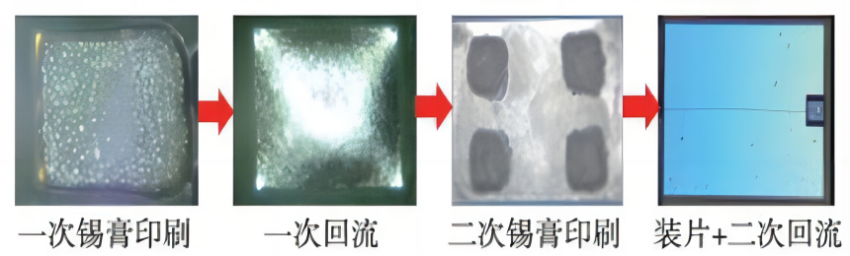

Txij li thaum lub nti npog ntawm lub solder tiv thaiv cov roj hauv lub solder los ntawm kev khiav tawm, lub qhov nyob rau hauv qab ntawm cov nti yog ntxiv txo los ntawm kev tshem tawm los yog txo cov roj solder coated. Cov txheej txheem tshiab ntawm reflow vuam nrog ob lub tshuab luam ntawv luam tawm tau txais yuav: ib lub tshuab luam ntawv luam tawm, ib qho reflow tsis npog QFN thiab liab qab nti tawm cov roj hauv cov khoom siv; Cov txheej txheem tshwj xeeb ntawm cov tshuab luam ntawv thib ob, thaj thiab cov reflux theem nrab yog qhia hauv daim duab 13.

Thaum lub 75μm tuab solder paste yog luam tawm thawj zaug, feem ntau ntawm cov roj nyob rau hauv lub solder tsis muaj nti npog khiav tawm ntawm qhov chaw, thiab lub thickness tom qab reflux yog hais txog 50μm. Tom qab ua tiav cov thawj reflux, me me squares yog luam tawm nyob rau saum npoo ntawm lub cooled solidified solder (nyob rau hauv thiaj li yuav txo tus nqi ntawm solder paste, txo cov roj spillover, txo los yog tshem tawm solder spatter), thiab solder muab tshuaj txhuam nrog ib tug tuab ntawm 50 μm (qhov kev ntsuam xyuas saum toj no qhia tau hais tias 100 μm yog qhov zoo tshaj plaws 50 μm 100 μm yog qhov zoo tshaj plaws 10 μm. μm = 50 μm), tom qab ntawd nruab lub nti, thiab rov qab los ntawm 80 s. Yuav luag tsis muaj qhov nyob rau hauv lub solder tom qab thawj printing thiab reflow, thiab solder paste nyob rau hauv lub thib ob printing yog me me, thiab lub vuam qhov yog me me, raws li qhia nyob rau hauv daim duab 14.

Tom qab ob lub tshuab luam ntawv ntawm cov tshuaj txhuam hniav, hollow kos duab

4.3 Kev txheeb xyuas ntawm cov kab noj hniav welding

Kev tsim khoom ntawm 2000 khoom (lub thickness ntawm thawj lub tshuab luam ntawv steel mesh yog 75 μm, lub thickness ntawm lub thib ob luam ntawv steel mesh yog 50 μm), lwm yam kev mob tsis hloov, random ntsuas ntawm 500 QFN thiab nti vuam kab noj hniav tus nqi, pom tias cov txheej txheem tshiab tom qab thawj reflux tsis muaj kab noj hniav, tom qab qhov thib ob reflux QFN kab noj hniav yog qhov siab tshaj plaws ntawm cov kab noj hniav. tus nqi ntawm cov nti yog 4.1%. Piv nrog rau cov txheej txheem luam ntawv ib leeg-paste welding thiab DOE optimized txheej txheem, lub vuam kab noj hniav yog txo qis, raws li qhia hauv daim duab 15. Tsis muaj cov kab nrib pleb tau pom tom qab kev sim ua haujlwm ntawm txhua yam khoom.

5 Cov ntsiab lus

Qhov kev ua kom zoo ntawm cov tshuaj txhuam luam ntawv luam tawm thiab lub sijhawm rov qab tuaj yeem txo qhov chaw vuam kab noj hniav, tab sis qhov vuam kab noj hniav tseem loj. Siv ob lub tshuab luam ntawv luam ntawv rov qab vuam cov txheej txheem tuaj yeem ua tau zoo thiab ua kom qhov vuam kab noj hniav ntau tshaj plaws. Qhov chaw vuam ntawm QFN Circuit Court liab qab nti tuaj yeem yog 4.4mm x4.1mm thiab 3.0mm x2.3mm feem ntau hauv cov khoom lag luam Cov kab noj hniav ntawm reflow vuam yog tswj hauv qab 5%, uas txhim kho qhov zoo thiab kev ntseeg siab ntawm reflow vuam. Kev tshawb fawb nyob rau hauv daim ntawv no muab ib qho tseem ceeb siv rau kev txhim kho qhov vuam kab noj hniav teeb meem ntawm loj cheeb tsam vuam nto.