Cov ncauj lus kom ntxaws ntawm SMT thaj thiab THT los ntawm qhov plug-in PCBA peb txheej txheej txheej txheej xim thiab cov thev naus laus zis tseem ceeb!

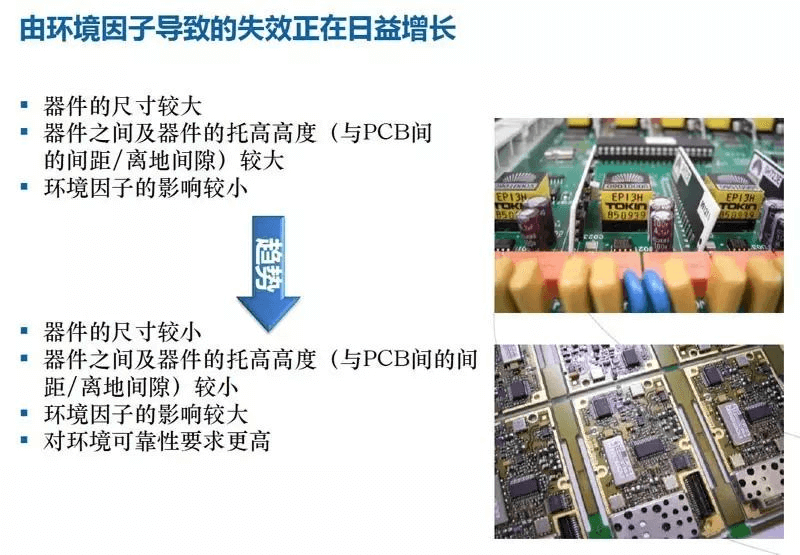

Raws li qhov loj ntawm PCBA Cheebtsam ua me dua thiab me dua, qhov ntom ntom yuav siab dua thiab siab dua; Qhov kev txhawb nqa qhov siab ntawm cov khoom siv thiab cov khoom siv (qhov sib nrug ntawm PCB thiab kev tshem tawm hauv av) kuj tau txais me me thiab me, thiab kev cuam tshuam ntawm ib puag ncig ntawm PCBA kuj nce ntxiv. Yog li, peb muab cov kev xav tau siab dua ntawm kev ntseeg siab ntawm PCBA ntawm cov khoom siv hluav taws xob.

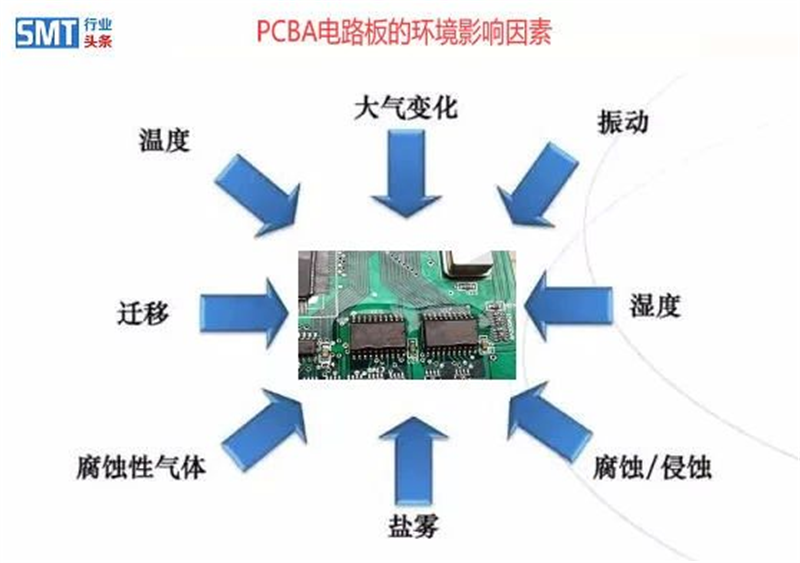

1.Environmental yam thiab lawv cov kev cuam tshuam

Cov xwm txheej ib puag ncig xws li av noo, plua plav, tshuaj tsuag ntsev, pwm, thiab lwm yam, tuaj yeem ua rau muaj teeb meem ntau yam ntawm PCBA.

Cov av noo

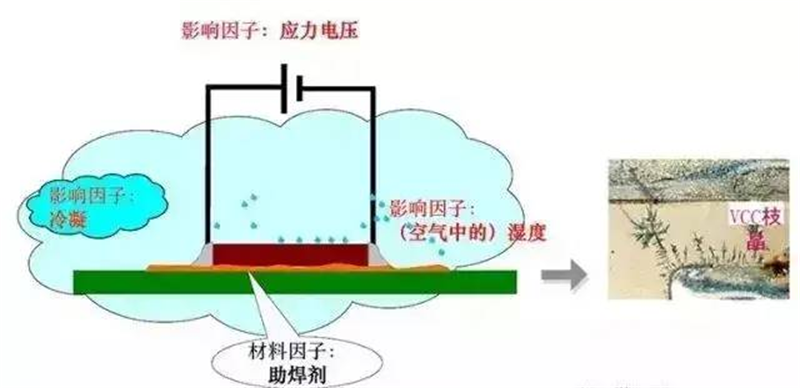

Yuav luag tag nrho cov khoom siv hluav taws xob PCB nyob rau hauv ib puag ncig sab nraud muaj kev pheej hmoo ntawm corrosion, ntawm cov dej yog qhov nruab nrab tseem ceeb tshaj plaws rau corrosion. Cov dej molecules me me txaus nkag mus rau qhov sib txawv mesh molecular ntawm qee cov ntaub ntawv polymer thiab nkag mus rau sab hauv lossis ncav cuag cov hlau hauv qab los ntawm lub pinhole ntawm txheej kom ua rau corrosion. Thaum huab cua nce mus txog qee qhov av noo, nws tuaj yeem ua rau PCB electrochemical tsiv teb tsaws, xau tam sim no thiab teeb liab distortion nyob rau hauv high zaus Circuit Court.

Vapor/humidity + ionic contaminants (ntsev, flux active agents) = conductive electrolytes + stress voltage = electrochemical migration

Thaum RH nyob rau hauv cov huab cua nce mus txog 80%, yuav muaj cov yeeb yaj kiab dej nrog lub thickness ntawm 5 ~ 20 molecules, thiab txhua yam ntawm cov molecules tuaj yeem txav tau yooj yim. Thaum muaj cov pa roj carbon, cov tshuaj electrochemical tuaj yeem tshwm sim.

Thaum RH nce mus txog 60%, txheej txheej ntawm cov cuab yeej yuav tsim 2 ~ 4 cov dej molecules tuab dej zaj duab xis, thaum muaj cov pa phem yaj hauv, yuav muaj tshuaj lom neeg;

Thaum RH <20% nyob rau hauv cov huab cua, yuav luag tag nrho corrosion phenomena nres.

Yog li ntawd, noo noo-pov thawj yog ib feem tseem ceeb ntawm kev tiv thaiv cov khoom.

Rau cov khoom siv hluav taws xob, cov dej noo tuaj hauv peb hom: nag, condensation thiab dej vapor. Dej yog ib qho electrolyte uas dissolves ntau ntawm corrosive ions uas corrode hlau. Thaum qhov kub ntawm ib feem ntawm cov khoom siv qis dua qhov "dej point" (kub), yuav muaj condensation rau saum npoo: cov khoom siv los yog PCBA.

Plua plav

Muaj cov plua plav hauv huab cua, cov plua plav adsorbed ion cov pa phem nyob hauv cov khoom siv hluav taws xob sab hauv thiab ua rau tsis ua haujlwm. Qhov no yog ib qho teeb meem tshwm sim nrog kev ua tsis tiav hauv hluav taws xob hauv cheeb tsam.

Plua plav muab faib ua ob hom: ntxhib plua plav yog txoj kab uas hla ntawm 2.5 ~ 15 microns ntawm cov khoom tsis sib xws, feem ntau yuav tsis ua txhaum, arc thiab lwm yam teeb meem, tab sis cuam tshuam rau kev sib cuag; Cov plua plav zoo yog cov khoom tsis sib xws nrog txoj kab uas hla tsawg dua 2.5 microns. Cov plua plav zoo muaj qee qhov adhesion ntawm PCBA (veneer), uas tsuas yog tshem tawm los ntawm cov txhuam hniav zoo li qub.

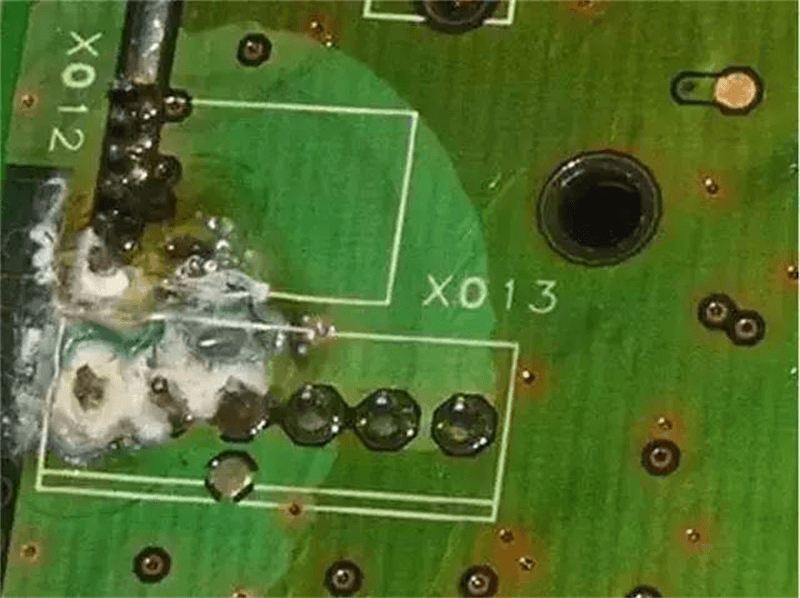

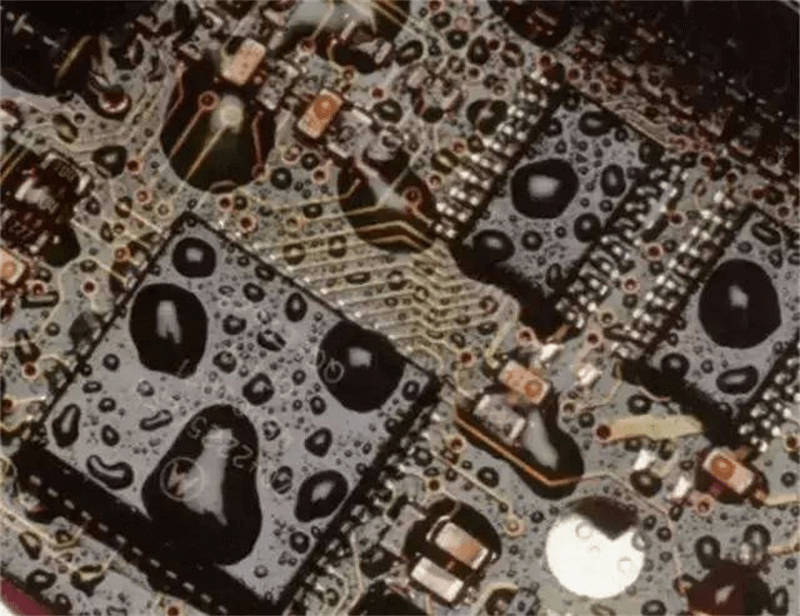

Kev phom sij ntawm plua plav:ib. Vim muaj plua plav nyob rau saum npoo ntawm PCBA, electrochemical corrosion yog generated, thiab tus nqi tsis ua hauj lwm nce; b. Plua plav + ntub dej + ntsev pos huab ua rau muaj kev puas tsuaj loj tshaj plaws rau PCBA, thiab cov khoom siv hluav taws xob tsis ua haujlwm yog qhov feem ntau hauv kev lag luam chemical thiab mining cheeb tsam ze ntawm ntug dej hiav txwv, suab puam (saline-alkali av) thiab sab qab teb ntawm Huaihe River thaum lub sij hawm mildew thiab lub caij los nag.

Yog li ntawd, kev tiv thaiv plua plav yog ib qho tseem ceeb ntawm cov khoom.

Ntsev tsuag

Kev tsim ntawm ntsev tsuag:Cov tshuaj tsuag ntsev yog tshwm sim los ntawm tej yam ntuj tso xws li dej hiav txwv nthwv dej, tides, atmospheric ncig (monsoon) siab, tshav ntuj thiab lwm yam. Nws yuav ya hauv av nrog cua, thiab nws cov concentration yuav txo qis nrog qhov kev ncua deb ntawm ntug dej hiav txwv. Feem ntau, qhov concentration ntawm ntsev tsuag yog 1% ntawm ntug dej hiav txwv thaum nws yog 1Km ntawm ntug dej hiav txwv (tab sis nws yuav ya mus deb dua nyob rau lub sij hawm typhoon).

Lub teeb meem ntawm ntsev tsuag:a. kev puas tsuaj rau cov txheej txheem hlau; b. Kev nrawm ntawm electrochemical corrosion ceev ua rau tawg ntawm cov hlau hlau thiab tsis ua haujlwm ntawm cov khoom.

Qhov zoo sib xws ntawm corrosion:a. Tes hws muaj ntsev, urea, lactic acid thiab lwm yam tshuaj, uas muaj cov nyhuv corrosive ntawm cov khoom siv hluav taws xob xws li tshuaj tsuag ntsev. Yog li ntawd, cov hnab looj tes yuav tsum tau hnav thaum sib dhos lossis siv, thiab cov txheej yuav tsum tsis txhob kov ntawm tes; b. Muaj halogens thiab acids nyob rau hauv lub flux, uas yuav tsum tau ntxuav thiab lawv residual concentration tswj.

Yog li ntawd, kev tiv thaiv ntsev tsuag yog ib qho tseem ceeb ntawm kev tiv thaiv cov khoom.

Pwm

Mildew, lub npe nrov rau filamentous fungi, txhais tau hais tias "moldy fungi," nyiam tsim mycelium luxuriant, tab sis tsis tsim cov txiv hmab txiv ntoo loj xws li nceb. Nyob rau hauv qhov chaw ntub dej thiab sov, ntau yam khoom loj hlob ntawm qhov muag liab qab qee qhov fuzzy, flocculent lossis cobweb zoo li cov cheeb tsam, uas yog pwm.

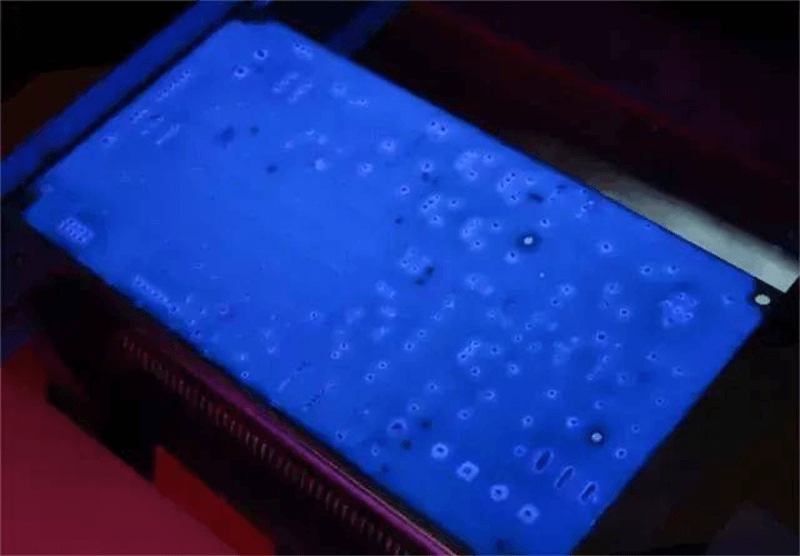

FIG. 5: PCB mildew tshwm sim

Kev puas tsuaj ntawm pwm:ib. pwm phagocytosis thiab propagation ua rau cov rwb thaiv tsev ntawm cov ntaub ntawv organic poob, kev puas tsuaj thiab tsis ua haujlwm; b. Cov metabolites ntawm pwm yog cov organic acids, uas cuam tshuam rau lub rwb thaiv tsev thiab hluav taws xob lub zog thiab tsim hluav taws xob arc.

Yog li ntawd, anti-pwm yog ib qho tseem ceeb ntawm cov khoom tiv thaiv.

Xav txog cov yam ntxwv saum toj no, kev ntseeg siab ntawm cov khoom yuav tsum tau lees paub zoo dua, nws yuav tsum raug cais tawm ntawm qhov chaw sab nraud kom tsawg li sai tau, yog li cov txheej txheem txheej txheej tau qhia.

Txheej txheej PCB tom qab txheej txheej txheej, nyob rau hauv lub teeb ci ntsa iab, cov txheej txheem qub tuaj yeem zoo nkauj heev!

Peb cov xim pleev ximhais txog txheej txheej txheej txheej tiv thaiv txheej txheej ntawm PCB. Nws yog feem ntau siv cov txheej txheem tom qab vuam txheej tam sim no, qee zaum hu ua txheej txheej thiab txheej txheej (Lus Askiv lub npe: txheej, txheej txheej). Nws yuav cais cov khoom siv hluav taws xob rhiab heev los ntawm ib puag ncig hnyav, tuaj yeem txhim kho kev nyab xeeb thiab kev ntseeg siab ntawm cov khoom siv hluav taws xob thiab txuas ntxiv lub neej kev pab cuam ntawm cov khoom. Peb cov xim pleev xim tuaj yeem tiv thaiv Circuit Court / cov khoom ntawm ib puag ncig xws li ya raws, cov pa phem, corrosion, kev ntxhov siab, poob siab, txhua yam kev co thiab thermal voj voog, thaum txhim kho cov khoom siv dag zog thiab rwb thaiv tsev cov yam ntxwv ntawm cov khoom.

Tom qab txheej txheej txheej ntawm PCB, tsim cov yeeb yaj kiab tiv thaiv pob tshab ntawm qhov chaw, tuaj yeem tiv thaiv dej thiab noo noo nkag, tsis txhob xau thiab luv luv.

2. Cov ntsiab lus tseem ceeb ntawm txheej txheej txheej

Raws li cov kev cai ntawm IPC-A-610E (Electronic Assembly Testing Standard), nws yog qhov tseem ceeb hauv cov hauv qab no:

Thaj tsam

1. Cov cheeb tsam uas tsis tuaj yeem coated:

Cov cheeb tsam uas xav tau kev sib txuas hluav taws xob, xws li cov ntaub qhwv kub, cov ntiv tes kub, cov hlau los ntawm qhov, qhov ntsuas qhov;

Roj teeb thiab roj teeb fixers;

Txuas;

fuse thiab casing;

Thaum tshav kub kub dissipation ntaus ntawv;

Jumper hlau;

Lub lens ntawm ib qho khoom siv kho qhov muag;

Potentiometer;

Sensor;

Tsis muaj kev sib khi kaw;

Lwm qhov chaw uas txheej txheej yuav cuam tshuam rau kev ua haujlwm lossis kev ua haujlwm.

2. Cov cheeb tsam uas yuav tsum tau coated: tag nrho cov pob qij txha, pins, Cheebtsam thiab conductors.

3. Cov cheeb tsam xaiv tau

Thickness

Thickness yog ntsuas ntawm lub tiaj tus, tsis muaj kev tiv thaiv, kho qhov chaw ntawm cov khoom siv hluav taws xob los yog ntawm cov phaj txuas uas ua tiav cov txheej txheem nrog cov khoom siv. Cov ntawv txuas yuav yog cov khoom siv tib yam li cov ntawv luam tawm lossis lwm cov ntaub ntawv tsis ntxeem tau, xws li hlau lossis iav. Kev ntsuas cov yeeb yaj kiab ntub dej kuj tuaj yeem siv los ua ib txoj hauv kev xaiv ntawm txheej thickness ntsuas, tsuav yog muaj ntaub ntawv hloov dua siab tshiab kev sib raug zoo ntawm ntub thiab qhuav zaj duab xis thickness.

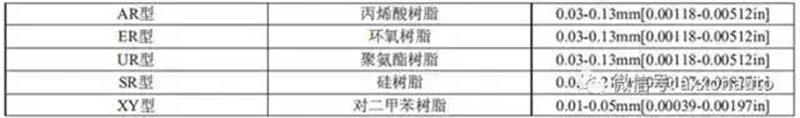

Table 1: Thickness range standard for every type of coating material

Test method ntawm thickness:

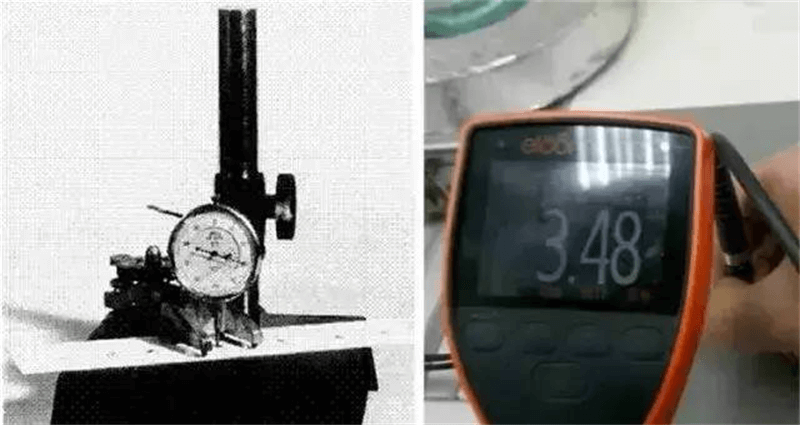

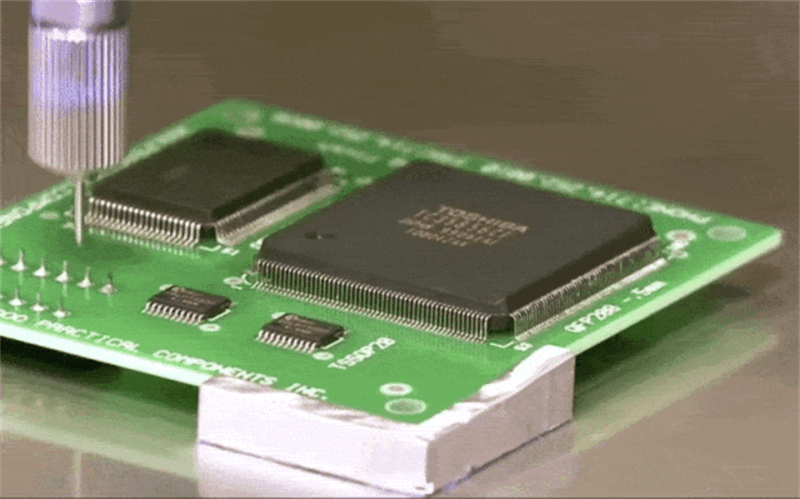

1. Dry film thickness Measuring tool: ib micrometer (IPC-CC-830B); b Dry Film thickness tester (hlau puag)

Daim duab 9. Micrometer qhuav zaj duab xis apparatus

2. Kev ntsuas cov yeeb yaj kiab ntub dej: qhov tuab ntawm cov yeeb yaj kiab ntub dej tuaj yeem tau txais los ntawm cov ntaub ntawv ntub dej ntub dej ntsuas ntsuas, thiab tom qab ntawd xam los ntawm kev faib ua feem ntawm cov kua nplaum cov ntsiab lus.

Thickness ntawm zaj duab xis qhuav

Hauv FIG. 10, cov yeeb yaj kiab ntub dej tau txais los ntawm cov yeeb yaj kiab ntub dej, thiab tom qab ntawd cov yeeb yaj kiab qhuav yog xam.

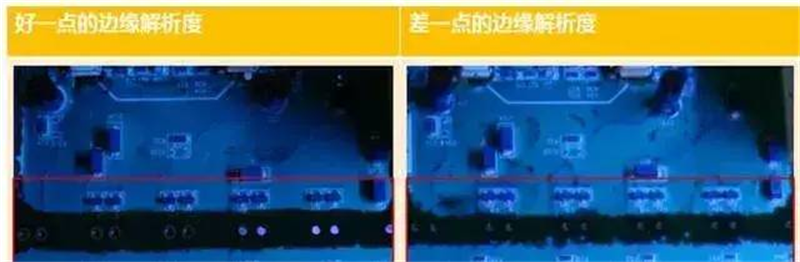

Ntug daws teeb meem

Txhais: Nyob rau hauv ib txwm muaj xwm txheej, tshuaj tsuag valve tsuag tawm ntawm kab ntug yuav tsis ncaj heev, yuav muaj ib qho burr. Peb txhais qhov dav ntawm burr raws li kev daws teeb meem ntawm ntug. Raws li qhia hauv qab no, qhov loj ntawm d yog tus nqi ntawm ntug kev daws teeb meem.

Lus Cim: Cov ntug kev daws teeb meem yog qhov me dua qhov zoo dua, tab sis cov neeg siv khoom sib txawv tsis zoo ib yam, yog li qhov tshwj xeeb coated ntug daws teeb meem ntev li ntev tau raws li cov neeg siv khoom xav tau.

Daim duab 11: Ntug daws teeb meem sib piv

Kev tsis sib xws

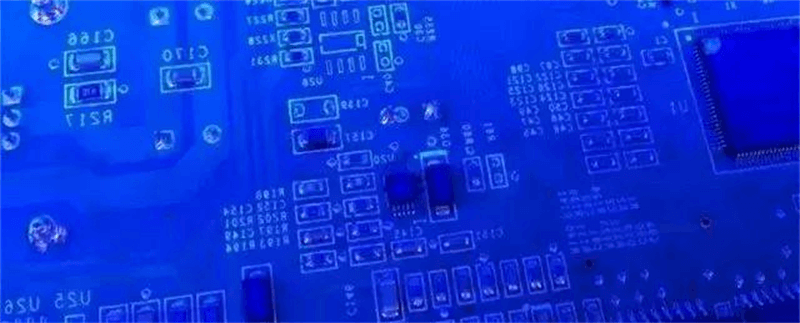

Cov kua nplaum yuav tsum zoo li cov tuab tuab thiab du thiab pob tshab zaj duab xis npog hauv cov khoom, qhov tseem ceeb ntawm cov kua nplaum uas muaj nyob hauv cov khoom saum toj no, yuav tsum yog tib lub thickness, tsis muaj txheej txheem teeb meem: tawg, stratification, txiv kab ntxwv kab, pa phem, capillary phenomenon, npuas.

Daim duab 12: Axial tsis siv neeg AC series tsis siv neeg txheej tshuab txheej nyhuv, uniformity zoo ib yam

3. Lub realization ntawm txheej txheej txheem

Txheej txheej txheej

1 Npaj

Npaj cov khoom thiab kua nplaum thiab lwm yam khoom tsim nyog;

Txiav txim siab qhov chaw tiv thaiv hauv zos;

Txiav txim siab cov txheej txheem tseem ceeb

2: ntxuav

Yuav tsum tau ntxuav nyob rau hauv lub sij hawm luv tshaj tom qab welding, kom tsis txhob vuam av yog nyuaj rau ntxuav;

Txiav txim siab seb cov pa phem tseem ceeb yog polar, lossis tsis yog polar, txhawm rau xaiv tus neeg saib xyuas kom tsim nyog;

Yog tias siv cov tshuaj ntxuav dej cawv, cov teeb meem kev nyab xeeb yuav tsum tau them rau: yuav tsum muaj qhov cua zoo thiab kev ua kom txias thiab ziab cov txheej txheem tom qab ntxuav, kom tsis txhob muaj cov kuab tshuaj volatilization los ntawm kev tawg hauv qhov cub;

Kev ntxuav dej, nrog alkaline ntxuav kua (emulsion) los ntxuav cov flux, thiab tom qab ntawd yaug nrog dej ntshiab los ntxuav cov kua ntxuav, kom ua tau raws li cov qauv tu;

3. Kev tiv thaiv daim npog ntsej muag (yog tias tsis siv cov khoom siv txheej txheej xaiv), uas yog, daim npog ntsej muag;

Yuav tsum xaiv cov yeeb yaj kiab uas tsis yog nplaum yuav tsis hloov daim ntawv daim kab xev;

Anti-static daim kab xev yuav tsum tau siv los tiv thaiv IC;

Raws li cov kev cai ntawm kev kos duab rau qee cov khoom siv los tiv thaiv kev tiv thaiv;

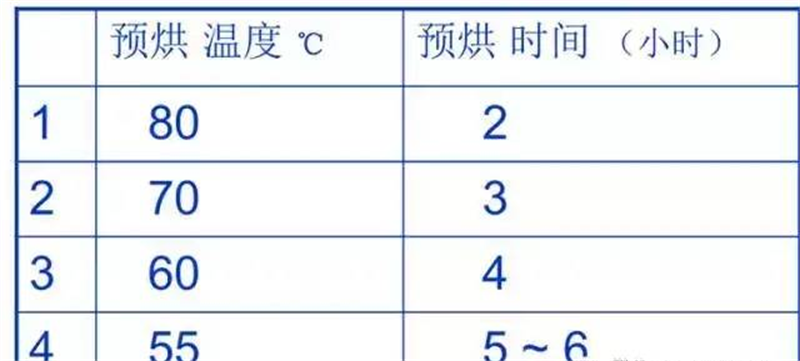

4. Dehumidify

Tom qab ntxuav, cov ntaub thaiv npog PCBA (cov khoom siv) yuav tsum tau ua kom qhuav thiab dehumidified ua ntej txheej;

Txiav txim siab qhov kub / lub sij hawm ua ntej ziab raws li qhov kub thiab txias tso cai los ntawm PCBA (cov khoom siv);

PCBA (cov khoom siv) tuaj yeem tso cai los txiav txim siab qhov kub / lub sijhawm ntawm lub rooj ua ntej ziab

5 Lub tsho tiv no

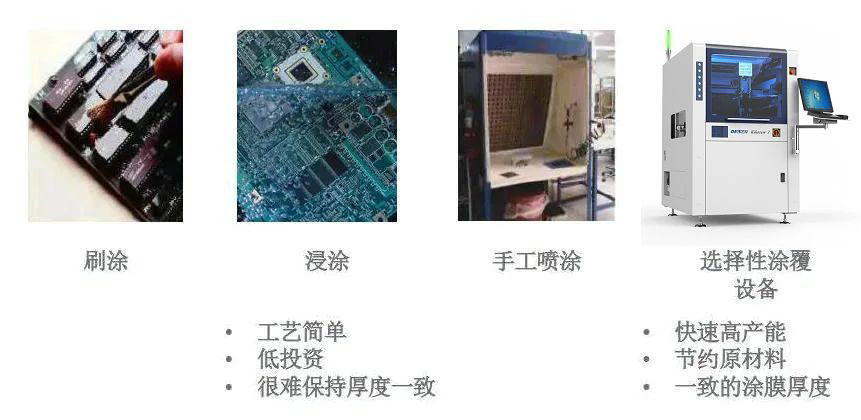

Cov txheej txheem ntawm txheej txheej yog nyob ntawm PCBA kev tiv thaiv cov cai, cov khoom siv txheej txheem uas twb muaj lawm thiab cov peev txheej uas twb muaj lawm, uas feem ntau ua tiav raws li hauv qab no:

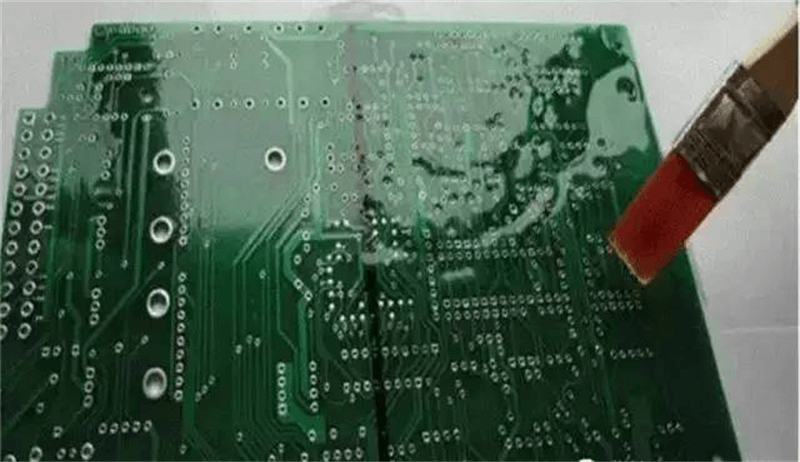

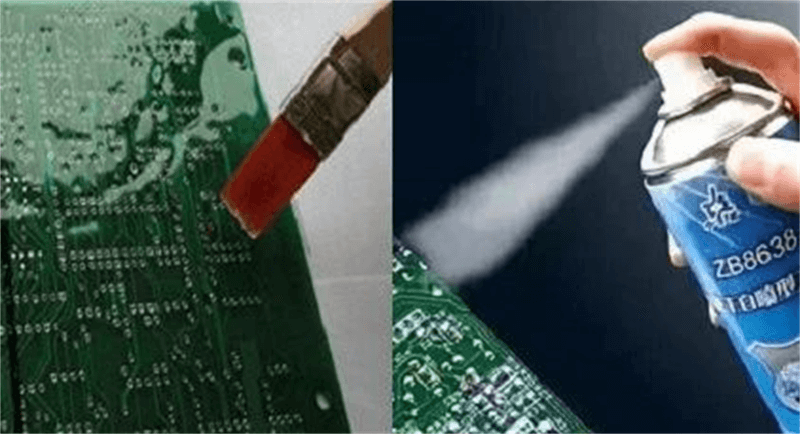

a. Txhuam los ntawm tes

Daim duab 13: Kev txhuam hniav ntawm tes

Txhuam txheej yog cov txheej txheem siv dav tshaj plaws, tsim nyog rau kev tsim khoom me me, PCBA qauv complex thiab ntom, yuav tsum tau tiv thaiv kev tiv thaiv ntawm cov khoom hnyav. Vim tias cov txhuam hniav tuaj yeem tswj tau ywj pheej, kom cov khoom tsis raug tso cai rau xim yuav tsis muaj kuab lom;

Txhuam txheej siv cov khoom siv tsawg tshaj plaws, tsim nyog rau tus nqi siab dua ntawm cov xim ntawm ob lub ntsiab lus;

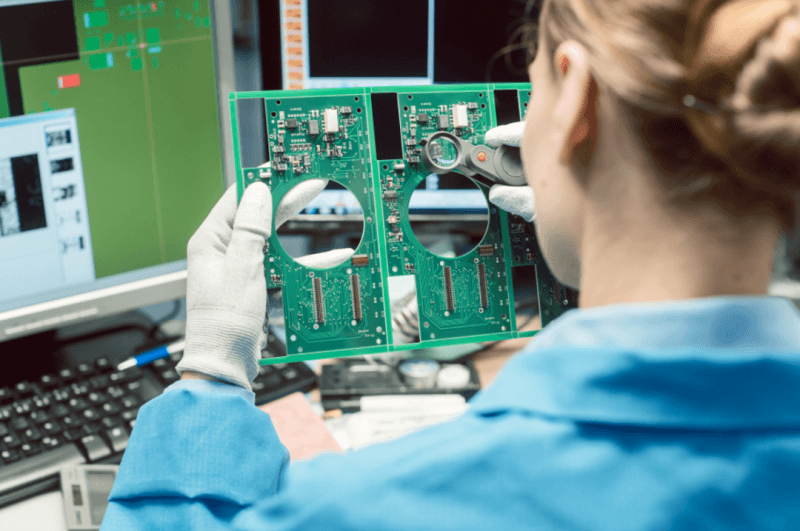

Cov txheej txheem pleev xim muaj qhov xav tau siab ntawm tus neeg teb xov tooj. Ua ntej kev tsim kho, cov duab kos thiab txheej txheej yuav tsum tau ua tib zoo zom, cov npe ntawm PCBA cov khoom yuav tsum raug lees paub, thiab cov khoom uas tsis tso cai rau coated yuav tsum tau muab cov cim qhov muag;

Cov neeg ua haujlwm tsis raug tso cai kov cov ntawv luam tawm nrog lawv txhais tes txhua lub sijhawm kom tsis txhob muaj kab mob;

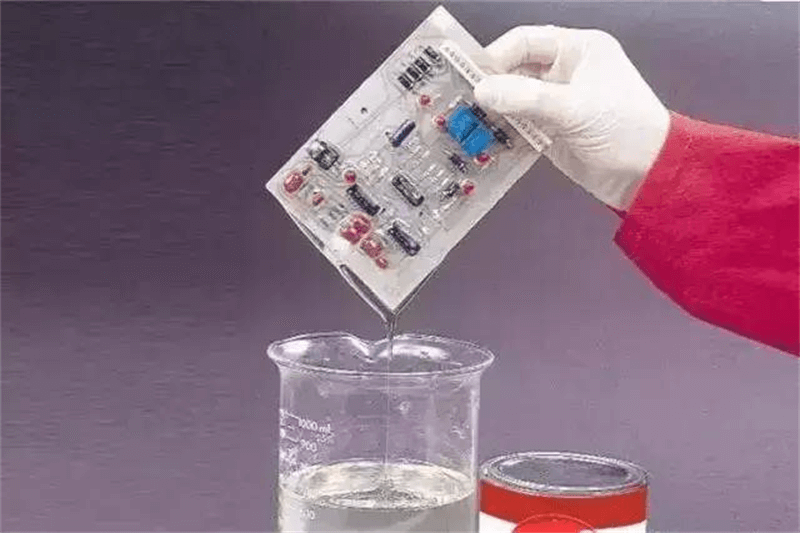

b.Dip los ntawm tes

Daim duab 14: Tes dip txheej txheej txheem

Cov txheej txheem dip txheej muab cov txheej txheem zoo tshaj plaws. Ib txheej txheej, txuas ntxiv tuaj yeem siv rau txhua qhov ntawm PCBA. Cov txheej txheem dip txheej yog tsis haum rau PCbas nrog adjustable capacitors, nplua-tuning magnetic cores, potentiometers, khob-zoo li tus hlau nplaum cores thiab qee qhov chaw uas tsis zoo sealing.

Qhov tseem ceeb ntawm cov txheej txheem dip txheej:

Kho qhov tsim nyog viscosity;

Tswj qhov ceev ntawm lub PCBA yog nqa los tiv thaiv npuas los ntawm kev sib sau. Feem ntau tsis ntau tshaj 1 meter ib ob;

c. Txau

Txau yog siv dav tshaj plaws, yooj yim rau kev lees txais cov txheej txheem, muab faib ua ob pawg hauv qab no:

① Kev siv tshuaj txau

Daim duab 15: Phau ntawv tshuaj tsuag txoj kev

Haum rau cov khoom ua haujlwm yog qhov nyuaj dua, nyuaj rau kev cia siab rau cov khoom siv automation huab hwm coj ntau lawm, kuj tsim nyog rau cov khoom lag luam ntau yam tab sis qhov teeb meem tsawg dua, tuaj yeem txau mus rau txoj haujlwm tshwj xeeb dua.

Nco tseg rau kev siv tshuaj tsuag: xim pos huab yuav ua rau muaj kuab paug rau qee yam khoom siv, xws li PCB plug-in, IC lub qhov (socket), qee qhov kev sib cuag rhiab thiab qee qhov chaw hauv av, cov khoom no yuav tsum tau ua tib zoo saib xyuas qhov kev ntseeg siab ntawm kev tiv thaiv vaj tse. Lwm qhov taw qhia yog tias tus neeg teb xov tooj yuav tsum tsis txhob kov lub ntsaws ntsaws nrog nws txhais tes txhua lub sijhawm kom tsis txhob kis kab mob ntawm lub ntsaws ntsaws.

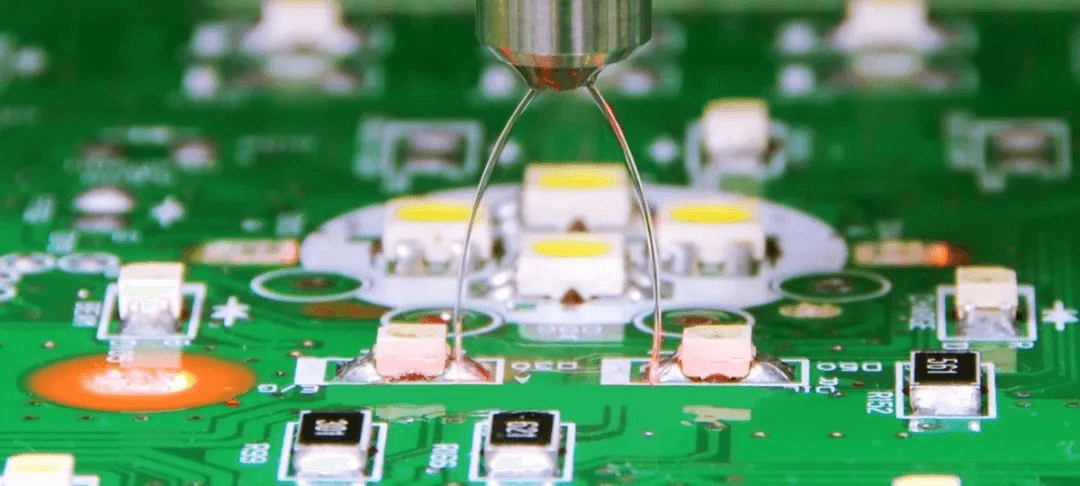

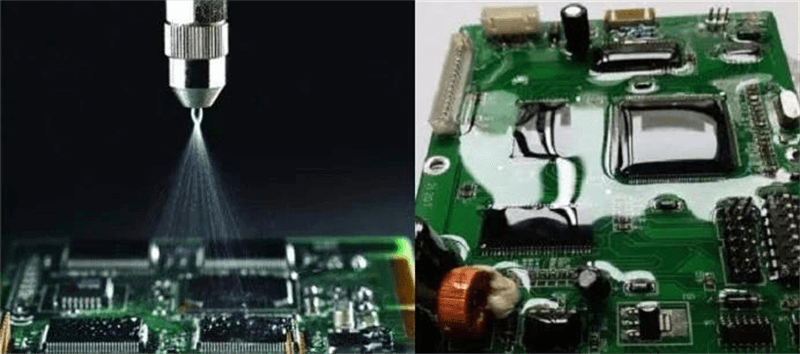

② Tsis siv neeg txau

Nws feem ntau yog hais txog tsis siv neeg txau nrog cov khoom siv txheej txheej xaiv. Haum rau ntau lawm, zoo sib xws, siab precision, me ntsis ib puag ncig muaj kuab paug. Nrog rau kev txhim kho kev lag luam, kev nce nqi ntawm kev ua haujlwm thiab cov kev cai nruj ntawm kev tiv thaiv ib puag ncig, cov khoom siv tshuaj tsuag tsis siv neeg yog maj mam hloov lwm txoj kev txheej txheej.

Nrog rau kev nce automation yuav tsum tau ntawm kev lag luam 4.0, lub hom phiaj ntawm kev lag luam tau hloov los ntawm kev muab cov cuab yeej txheej tsim nyog los daws qhov teeb meem ntawm tag nrho cov txheej txheem txheej. Tsis siv neeg xaiv txheej tshuab - txheej txheej yog thiab tsis muaj pov tseg ntawm cov khoom siv, haum rau ntau qhov txheej txheej, haum rau ntau qhov ntau ntawm peb cov xim pleev xim.

Kev sib piv ntawmtsis siv neeg txheej tshuabthiabtxheej txheem txheej txheem

Tsoos PCBA peb-pov thawj xim txheej:

1) Txhuam txheej: muaj npuas, nthwv dej, txhuam cov plaub hau tshem tawm;

2) Kev Sau: qeeb dhau, qhov tseeb tsis tuaj yeem tswj tau;

3) Soaking tag nrho cov khoom: cov xim khib nyiab heev, qeeb ceev;

4) Txau phom txau: txhawm rau tiv thaiv kev tiv thaiv, ntws ntau dhau

Txheej tshuab txheej:

1) Tus nqi ntawm cov tshuaj tsuag pleev xim, tshuaj tsuag xim txoj hauj lwm thiab cheeb tsam tau teeb tsa kom raug, thiab tsis tas yuav ntxiv cov neeg los so lub rooj tsavxwm tom qab cov tshuaj pleev xim.

2) Qee qhov txuas txuas nrog qhov sib txawv loj ntawm ntug ntawm lub phaj tuaj yeem pleev xim ncaj qha yam tsis muaj kev txhim kho, txuag cov neeg ua haujlwm ntawm lub phaj.

3) Tsis muaj roj volatilization, kom muaj kev ua haujlwm huv.

4) Txhua lub substrate tsis tas yuav siv cov khoom siv los npog cov yeeb yaj kiab carbon, tshem tawm qhov muaj peev xwm ntawm kev sib tsoo.

5) Peb cov xim pleev xim txheej tuab, zoo heev txhim kho kev tsim khoom thiab cov khoom zoo, tab sis kuj zam cov xim khib nyiab.

PCBA tsis siv neeg peb lub tshuab pleev xim pleev xim, tshwj xeeb yog tsim los rau kev txau peb cov tshuaj pleev xim ntse txau cov cuab yeej. Vim hais tias cov khoom yuav tsum tau txau thiab cov tshuaj tsuag cov kua siv sib txawv, lub tshuab txheej hauv kev tsim kho cov khoom siv xaiv kuj sib txawv, peb lub tshuab pleev xim pleev xim siv lub tshuab siv lub tshuab tswj xyuas qhov tseeb, tuaj yeem paub qhov kev sib txuas ntawm peb-axis, tib lub sij hawm nruab nrog lub koob yees duab qhov chaw thiab taug qab qhov system, tuaj yeem tswj tau qhov chaw txau.

Peb lub tshuab pleev xim pleev xim, tseem hu ua peb lub tshuab pleev xim pleev xim, peb lub tshuab pleev xim pleev xim pleev xim, peb lub tshuab pleev xim roj pleev xim, peb lub tshuab pleev xim pleev xim, tshwj xeeb rau kev tswj dej, ntawm PCB nto npog nrog ib txheej ntawm peb cov xim los tiv thaiv, xws li impregnation, txau lossis kiv txheej txheej txheej ntawm PCB nto npog nrog txheej txheej ntawm photoresist.

Yuav ua li cas los daws qhov tshiab era ntawm peb cov tshuaj tiv thaiv xim txheej thov, tau dhau los ua qhov teeb meem ceev kom daws tau hauv kev lag luam. Cov khoom siv txheej txheej tsis siv neeg sawv cev los ntawm kev xaiv cov txheej txheem txheej txheem coj tau txoj hauv kev tshiab ntawm kev ua haujlwm,txheej yog thiab tsis muaj pov tseg ntawm cov ntaub ntawv, qhov zoo tshaj plaws haum rau ib tug loj tus naj npawb ntawm peb anti-xim txheej.