【Cov khoom qhuav】 Kev soj ntsuam tob ntawm SMT yog vim li cas thiaj siv cov kua nplaum liab?(2023 Essence Edition), koj tsim nyog nws!

SMT nplaum, tseem hu ua SMT nplaum, SMT liab nplaum, feem ntau yog xim liab (tseem daj lossis dawb) muab tshuaj txhuam sib npaug nrog cov tawv tawv, xim, hnyav thiab lwm cov nplaum, feem ntau yog siv los kho cov khoom ntawm lub rooj tsavxwm luam ntawv, feem ntau faib los ntawm kev xa tawm. los yog steel screen printing txoj kev.Tom qab affixing cov khoom, muab tso rau hauv qhov cub los yog reflow rauv rau cua sov thiab hardening.Qhov txawv ntawm nws thiab cov muab tshuaj txhuam yog tias nws tau kho tom qab cua sov, nws qhov chaw txias txias yog 150 ° C, thiab nws yuav tsis yaj tom qab reheating, uas yog hais tias, cov txheej txheem kub hardening ntawm thaj yog irreversible.Kev siv cov nyhuv ntawm SMT nplaum yuav sib txawv vim cov thermal curing tej yam kev mob, cov khoom txuas nrog, cov cuab yeej siv, thiab qhov chaw ua haujlwm.Cov nplaum nplaum yuav tsum raug xaiv raws li cov txheej txheem luam tawm Circuit Board (PCBA, PCA).

Cov yam ntxwv, daim ntawv thov thiab kev cia siab ntawm SMT thaj nplaum

SMT liab kua nplaum yog ib hom polymer compound, cov khoom tseem ceeb yog cov khoom siv hauv paus (uas yog, cov khoom siv molecular siab), muab tub lim, kho tus neeg sawv cev, lwm yam khoom ntxiv thiab lwm yam.SMT liab kua nplaum muaj viscosity fluidity, kub yam ntxwv, wetting yam ntxwv thiab hais txog.Raws li cov yam ntxwv ntawm cov kua nplaum liab, hauv kev tsim khoom, lub hom phiaj ntawm kev siv cov kua nplaum liab yog ua kom cov khoom ruaj khov rau saum npoo ntawm PCB kom tsis txhob poob.Yog li ntawd, cov nplaum nplaum yog ib qho kev noj qab haus huv ntawm cov khoom lag luam tsis tseem ceeb, thiab tam sim no nrog kev txhim kho txuas ntxiv ntawm PCA tsim thiab txheej txheem, los ntawm lub qhov rov qab thiab ob sab reflow vuam tau pom, thiab PCA mounting txheej txheem siv cov nplaum nplaum. yog qhia txog qhov sib txawv ntawm tsawg thiab tsawg.

Lub hom phiaj ntawm kev siv SMT nplaum

① Tiv thaiv cov khoom los ntawm kev poob hauv yoj soldering (yoj txheej txheem soldering).Thaum siv yoj yoj soldering, cov khoom yog tsau rau ntawm cov ntawv luam tawm los tiv thaiv cov khoom los ntawm kev poob thaum cov ntawv luam tawm dhau los ntawm cov zawj.

② Tiv thaiv rau sab nraud ntawm cov khoom sib tsoo los ntawm kev sib tsoo hauv qhov rov qab vuam (ob npaug-sided reflow vuam txheej txheem).Nyob rau hauv cov txheej txheem ob-sab reflow welding, thiaj li yuav tiv thaiv cov khoom loj ntawm sab soldered los ntawm kev poob vim yog lub tshav kub melting ntawm solder, yuav tsum tau ua SMT patch kua nplaum.

③ Tiv thaiv kom tsis txhob txav thiab sawv ntawm cov khoom (reflow vuam txheej txheem, txheej txheem ua ntej txheej).Siv nyob rau hauv reflow vuam txheej txheem thiab pre-txheej txheej txheem los tiv thaiv kev khiav hauj lwm thiab riser thaum lub sij hawm mounting.

④ Mark (yoj vuam, reflow vuam, txheej ua ntej).Tsis tas li ntawd, thaum cov ntawv luam tawm thiab cov khoom hloov pauv hauv cov khoom siv, cov nplaum nplaum yog siv rau kev kos.

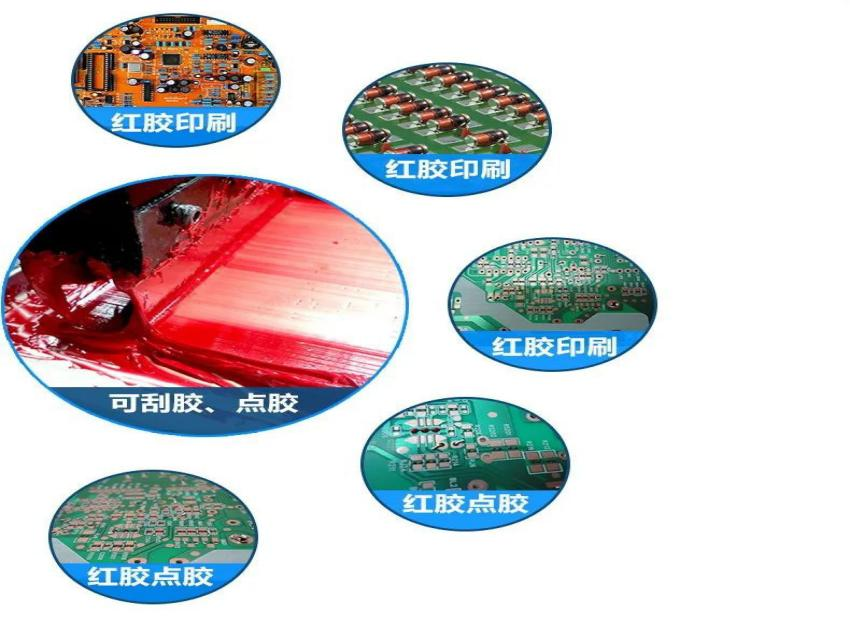

SMT nplaum yog cais raws li hom kev siv

a) Scraping hom: sizing yog nqa tawm los ntawm kev luam ntawv thiab scraping hom steel mesh.Txoj kev no yog siv dav tshaj plaws thiab tuaj yeem siv ncaj qha rau ntawm cov xovxwm solder paste.Cov hlau mesh qhov yuav tsum tau txiav txim siab raws li hom ntawm qhov chaw, kev ua haujlwm ntawm lub substrate, thickness thiab qhov loj thiab cov duab ntawm lub qhov.Nws qhov zoo yog kev kub ceev, kev ua haujlwm siab thiab tus nqi qis.

b) Dispensing type: Cov kua nplaum yog siv rau ntawm lub rooj tsav xwm luam tawm los ntawm cov khoom siv dispensing.Cov khoom siv tshwj xeeb yog xav tau, thiab tus nqi siab.Cov khoom siv dispensing yog siv cov cua compressed, cov kua nplaum liab los ntawm qhov tshwj xeeb dispensing lub taub hau mus rau lub substrate, qhov luaj li cas ntawm cov kua nplaum taw tes, ntau npaum li cas, los ntawm lub sij hawm, lub siab lub raj txoj kab uas hla thiab lwm yam tsis tswj, dispensing tshuab muaj ib tug saj zawg zog ua hauj lwm. .Rau qhov sib txawv, peb tuaj yeem siv lub taub hau sib txawv, teeb tsa kev hloov pauv, koj tuaj yeem hloov cov duab thiab qhov ntau ntawm cov nplaum nplaum, txhawm rau ua tiav cov txiaj ntsig, qhov zoo yog yooj yim, hloov tau thiab ruaj khov.Qhov tsis zoo yog qhov yooj yim kom muaj hlau kos duab thiab npuas.Peb tuaj yeem kho qhov kev khiav hauj lwm tsis, ceev, lub sij hawm, huab cua siab, thiab kub kom txo tau cov shortcomings.

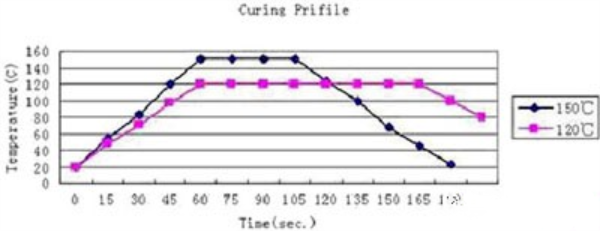

SMT thaj adhesive raug kho mob

| Curing kub | Lub sijhawm kho |

| 100 ℃ | 5 feeb |

| 120 ℃ | 150 vib nas this |

| 150 ℃ | 60 vib nas this |

Nco tseg:

1, qhov kub thiab txias ntau dua thiab lub sijhawm kho lub sijhawm ntev dua, qhov kev sib khi muaj zog dua.

2, vim hais tias qhov kub ntawm cov nplaum nplaum yuav hloov nrog qhov loj ntawm cov substrate qhov chaw thiab lub mounting txoj hauj lwm, peb pom zoo kom nrhiav tau qhov zoo tshaj plaws hardening tej yam kev mob.

Cia ntawm SMT thaj ua rau thaj

Nws tuaj yeem khaws cia rau 7 hnub ntawm chav tsev kub, rau ntau tshaj 6 lub hlis ntawm tsawg dua 5 ° C, thiab ntau tshaj 30 hnub ntawm 5 ~ 25 ° C.

SMT nplaum kev tswj

Vim tias SMT thaj liab kua nplaum raug cuam tshuam los ntawm qhov kub thiab txias nrog nws tus kheej viscosity, fluidity, ntub dej thiab lwm yam ntxwv, yog li SMT thaj liab kua nplaum yuav tsum muaj qee yam kev siv thiab kev tswj hwm tus qauv.

1) Cov kua nplaum liab yuav tsum muaj tus lej tshwj xeeb, raws li tus lej pub, hnub tim, ntaus rau tus lej.

2) Cov kua nplaum liab yuav tsum muab cia rau hauv lub tub yees ntawm 2 ~ 8 ° C kom tsis txhob muaj cov yam ntxwv cuam tshuam vim qhov kub thiab txias.

3) Cov kua nplaum liab yuav tsum tau ua kom sov hauv chav sov li 4 teev, nyob rau hauv qhov kev txiav txim ntawm kev siv thawj zaug.

4) Rau kev ua haujlwm, cov kua nplaum liab ntawm lub hose yuav tsum tau defrosted, thiab cov kua nplaum liab uas tsis tau siv yuav tsum muab tso rau hauv lub tub yees kom khaws cia, thiab cov kua nplaum qub thiab cov kua nplaum tshiab tsis tuaj yeem sib xyaw.

5) Txhawm rau kom raug sau rau hauv daim ntawv ntsuas kub rov qab, rov qab tus neeg kub thiab lub sij hawm rov qab los, tus neeg siv yuav tsum paub meej tias qhov ua tiav ntawm qhov ntsuas kub rov qab ua ntej siv.Feem ntau, cov kua nplaum liab tsis tuaj yeem siv dhau los.

Txheej txheem cov yam ntxwv ntawm SMT thaj nplaum

Kev sib txuas lub zog: SMT nplaum yuav tsum muaj kev sib txuas muaj zog, tom qab ua kom tawv, txawm tias qhov kub ntawm qhov kub ntawm lub solder tsis tev.

Dot txheej: Tam sim no, txoj kev faib tawm ntawm cov ntawv luam tawm feem ntau yog dot txheej, yog li cov kua nplaum yuav tsum muaj cov khoom nram qab no:

① Kho kom haum rau ntau yam txheej txheem mounting

Yooj yim los teeb tsa cov khoom ntawm txhua qhov khoom

③ Yooj yim rau hloov pauv cov khoom sib xyaw

④ Stable dot txheej tus nqi

Kho kom haum rau high-speed tshuab: thaj nplaum siv tam sim no yuav tsum ua kom tau raws li qhov kev kub ceev ntawm qhov chaw txheej thiab lub tshuab ua haujlwm siab ceev, tshwj xeeb, uas yog, qhov kub ceev txheej txheej tsis muaj hlau kos, thiab qhov ntawd yog, kev kub ceev. mounting, luam ntawv board nyob rau hauv cov txheej txheem kis tau tus mob, cov nplaum los xyuas kom meej tias cov khoom tsis txav.

Hlau daim duab, lub cev qhuav dej: ib zaug cov nplaum nplaum nplaum rau ntawm lub ncoo, cov khoom siv tsis tuaj yeem ua tiav cov hluav taws xob sib txuas nrog cov ntawv luam tawm, yog li cov nplaum nplaum yuav tsum tsis muaj hlau kos thaum txheej txheej, tsis muaj kev sib tsoo tom qab txheej, yog li tsis txhob ua qias tuaj. pad.

Tsawg-kub curing: Thaum kho, lub tshav kub-resistant plug-in Cheebtsam welded nrog yoj crest welding yuav tsum dhau los ntawm lub reflow vuam rauv, yog li cov hardening tej yam kev mob yuav tsum tau raws li qhov kub thiab txias thiab lub sij hawm luv luv.

Kev kho tus kheej: Nyob rau hauv cov txheej txheem reflow welding thiab pre-txheej txheej, cov nplaum nplaum yog kho thiab kho ua ntej lub solder melts, yog li nws yuav tiv thaiv cov khoom los ntawm sinking rau hauv lub solder thiab nws tus kheej-hloov kho.Hauv kev teb rau qhov no, manufacturers tau tsim ib qho kev kho tus kheej.

SMT nplaum cov teeb meem tshwm sim, tsis xws luag thiab tsom xam

kev poob siab

Lub zog thrust ntawm 0603 capacitor yog 1.0KG, qhov tsis kam yog 1.5KG, lub zog thrust ntawm 0805 capacitor yog 1.5KG, qhov tsis kam yog 2.0KG, uas tsis tuaj yeem ncav cuag qhov siab saum toj no, qhia tias lub zog tsis txaus. .

Feem ntau tshwm sim los ntawm cov laj thawj hauv qab no:

1, cov kua nplaum tsis txaus.

2, colloid tsis yog 100% kho.

3, PCB pawg thawj coj saib lossis cov khoom sib kis.

4, lub colloid nws tus kheej yog nkig, tsis muaj zog.

Thixotropic instability

Lub 30ml syringe kua nplaum yuav tsum tau ntaus kaum tawm txhiab zaus los ntawm huab cua siab kom siv tau, yog li cov kua nplaum nws tus kheej yuav tsum muaj cov thixotropy zoo heev, txwv tsis pub nws yuav ua rau cov kua nplaum tsis ruaj khov, cov kua nplaum tsawg dhau lawm, uas yuav ua rau cov kua nplaum zoo heev. kom tsis muaj zog txaus, ua rau cov khoom tawg thaum lub sij hawm yoj soldering, ntawm qhov tsis sib xws, cov kua nplaum ntau dhau, tshwj xeeb tshaj yog rau cov khoom me me, yooj yim rau lo rau hauv ncoo, tiv thaiv kev sib txuas hluav taws xob.

Cov kua nplaum tsis txaus los yog qhov dej xau

Yog vim li cas thiab Countermeasures:

1, lub tshuab luam ntawv tsis tu ncua tsis tu ncua, yuav tsum tau ntxuav nrog ethanol txhua 8 teev.

2, colloid muaj impurities.

3, qhov qhib ntawm lub mesh board yog tsis tsim nyog me me los yog lub dispensing siab me me heev, tsim cov kua nplaum tsis txaus.

4, muaj npuas nyob rau hauv lub colloid.

5. Yog hais tias lub taub hau dispensing raug thaiv, lub dispensing nozzle yuav tsum tau muab ntxuav tam sim ntawd.

6, qhov kub thiab txias ntawm lub taub hau dispensing tsis txaus, qhov kub ntawm lub taub hau yuav tsum tau teem rau ntawm 38 ℃.

hlau kos duab

Lub npe hu ua daim duab kos yog qhov tshwm sim uas cov nplaum nplaum tsis tawg thaum xa tawm, thiab cov nplaum nplaum txuas nrog hauv txoj kev filamentous nyob rau hauv cov kev taw qhia ntawm lub taub hau dispensing.Muaj ntau cov xov hlau, thiab cov ntaub nplaum nplaum yog npog ntawm cov ntaub ntawv luam tawm, uas yuav ua rau cov vuam tsis zoo.Tshwj xeeb tshaj yog thaum qhov loj dua, qhov tshwm sim no feem ntau tshwm sim thaum lub ntsiab lus txheej lub qhov ncauj.Kev kos duab ntawm cov nplaum nplaum yog feem ntau cuam tshuam los ntawm cov cuab yeej kos duab ntawm nws cov khoom tseem ceeb cob thiab qhov teeb tsa ntawm cov ntsiab lus txheej txheej.

1, nce lub dispensing stroke, txo qhov txav ceev, tab sis nws yuav txo koj cov khoom ntaus.

2, qhov tsawg dua viscosity, siab thixotropy ntawm cov khoom, qhov me dua qhov nyiam kos, yog li sim xaiv xws li cov nplaum nplaum.

3, qhov ntsuas kub ntawm qhov ntsuas kub yog me ntsis siab dua, yuam kom kho kom tsis muaj viscosity, siab thixotropic thaj kua nplaum, tom qab ntawd kuj xav txog lub sijhawm cia ntawm cov nplaum nplaum thiab lub siab ntawm lub taub hau dispensing.

cav

Lub fluidity ntawm thaj yuav ua rau tawg.Qhov teeb meem feem ntau ntawm kev sib tsoo yog tias tso ntev dhau tom qab qhov chaw txheej yuav ua rau tawg.Yog tias cov nplaum nplaum txuas ntxiv mus rau lub ncoo ntawm lub rooj tsav xwm luam tawm, nws yuav ua rau cov vuam tsis zoo.Thiab lub cev qhuav dej ntawm cov nplaum nplaum rau cov khoom siv nrog cov pins siab, nws tsis kov lub cev tseem ceeb ntawm cov khoom, uas yuav ua rau tsis txaus adhesion, yog li lub cev qhuav dej ntawm cov nplaum nplaum uas yooj yim rau kev sib tsoo yog qhov nyuaj rau kwv yees, yog li qhov pib qhov chaw ntawm nws cov dot txheej nyiaj kuj nyuaj.Nyob rau hauv kev pom ntawm qhov no, peb yuav tsum xaiv cov uas tsis yooj yim rau lub cev qhuav dej, uas yog, lub thaj uas yog siab heev nyob rau hauv co kua.Rau lub cev qhuav dej tshwm sim los ntawm kev tso ntev dhau lawm tom qab qhov chaw txheej, peb tuaj yeem siv sijhawm luv luv tom qab qhov chaw txheej los ua kom tiav cov nplaum nplaum, kho kom tsis txhob muaj.

Cheebtsam offset

Cheebtsam offset yog qhov tshwm sim tsis zoo uas yooj yim tshwm sim hauv cov tshuab SMT siab, thiab cov laj thawj tseem ceeb yog:

1, yog lub tshuab luam ntawv siab ceev txav ntawm XY kev taw qhia tshwm sim los ntawm qhov offset, thaj chaw nplaum txheej ntawm cov khoom me me ua rau qhov tshwm sim no, yog vim li cas qhov adhesion tsis tshwm sim los ntawm.

2, tus nqi ntawm cov kua nplaum nyob rau hauv cov khoom tsis sib xws (xws li: ob lub ntsiab lus kua nplaum nyob rau hauv IC, ib qho kua nplaum yog qhov loj thiab ib qho kua nplaum me me), lub zog ntawm cov kua nplaum tsis sib npaug thaum nws sov thiab kho, thiab qhov kawg nrog cov kua nplaum tsawg yog yooj yim rau offset.

Tshaj yoj soldering tawm qhov chaw

Cov laj thawj yog complex:

1. Lub zog nplaum ntawm lub thaj tsis txaus.

2. Nws tau raug cuam tshuam ua ntej yoj soldering.

3. Muaj ntau qhov seem ntawm qee yam khoom.

4, lub colloid tsis resistant rau kub kub

Patch kua nplaum mix

Cov chaw tsim khoom sib txawv ntawm cov nplaum nplaum hauv cov tshuaj muaj pes tsawg leeg muaj qhov sib txawv, kev siv sib xyaw yog ib qho yooj yim los tsim ntau yam tsis zoo: 1, kho nyuaj;2, cov nplaum relay tsis txaus;3, dhau yoj soldering tawm loj.

Cov tshuaj yog: kom huv si ntxuav lub mesh board, scraper, dispensing thiab lwm yam uas yooj yim rau kev sib tov, thiab tsis txhob sib tov ntau hom ntawm patch kua nplaum.