[Cov khoom qhuav] SMT patch slices ntawm tin paste kev faib tawm hauv kev ua, koj puas paub ntau npaum li cas? (2023 Essence), koj tsim nyog nws!

Ntau yam khoom siv raw khoom siv hauv SMT thaj ua haujlwm. Lub tinnote yog qhov tseem ceeb tshaj. Qhov zoo ntawm cov tin paste yuav cuam tshuam ncaj qha rau kev vuam zoo ntawm SMT thaj ua haujlwm. Xaiv ntau hom tinnuts. Cia kuv qhia luv luv txog kev faib cov tin paste:

Weld paste yog ib hom kev sib xyaw ua ke ntawm cov hmoov sib tov nrog cov tshuaj txhuam zoo li cov khoom siv vuam (rosin, diluent, stabilizer, thiab lwm yam) nrog rau kev ua haujlwm welded. Hais txog qhov hnyav, 80 ~ 90% yog hlau alloys. Nyob rau hauv cov nqe lus ntawm ntim, hlau thiab solder accounted rau 50%.

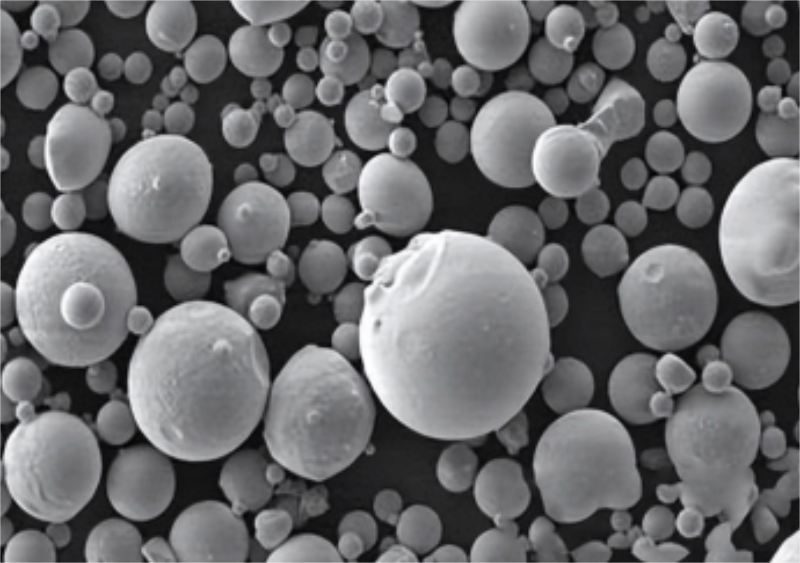

Daim duab 3 Kaum muab tshuaj txhuam granules (SEM) (sab laug)

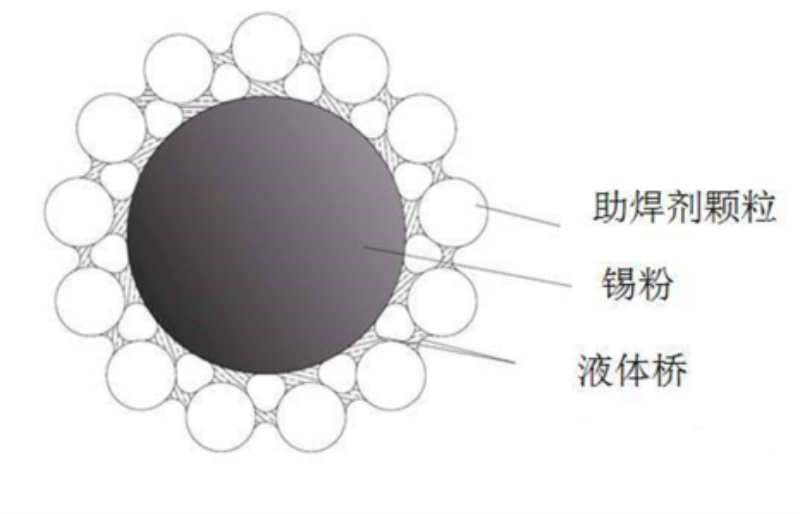

Daim duab 4 Daim duab tshwj xeeb ntawm tin hmoov nto npog (txoj cai)

Lub solder paste yog tus nqa ntawm tin hmoov hais. Nws muab cov khoom tsim nyog tshaj plaws degeneration thiab av noo los txhawb kev xa hluav taws xob mus rau thaj tsam SMT thiab txo qhov nro ntawm cov kua ntawm lub vuam. Cov khoom xyaw sib txawv qhia cov haujlwm sib txawv:

① Cov kuab tshuaj:

Cov kuab tshuaj ntawm cov khoom siv weld no muaj qhov sib txawv ntawm kev hloov kho tsis siv neeg hauv cov txheej txheem kev ua haujlwm ntawm tin paste, uas muaj kev cuam tshuam ntau dua rau lub neej ntawm weld paste.

② Resin:

Nws ua lub luag haujlwm tseem ceeb hauv kev ua kom cov adhesion ntawm tin paste thiab kho thiab tiv thaiv PCB los ntawm re-oxidation tom qab vuam. Cov khoom xyaw tseem ceeb no muaj lub luag haujlwm tseem ceeb hauv kev txhim kho ntawm qhov chaw.

③ Tus neeg ua haujlwm:

Nws ua lub luag haujlwm ntawm kev tshem tawm cov tshuaj oxidized ntawm PCB tooj liab zaj duab xis nto txheej thiab ib feem SMT thaj chaw, thiab muaj cov nyhuv ntawm kev txo qhov nro ntawm cov tin thiab lead kua.

④ Tentacle:

Tsis siv neeg hloov kho ntawm viscosity ntawm weld paste plays lub luag haujlwm tseem ceeb hauv kev luam ntawv los tiv thaiv tus Tsov tus tw thiab adhesion.

Ua ntej, raws li qhov muaj pes tsawg leeg ntawm solder paste classification

1, cov hmoov txhuas txhuas: muaj cov khoom siv lead ua, muaj kev phom sij ntau dua rau ib puag ncig thiab tib neeg lub cev, tab sis cov nyhuv vuam zoo, thiab tus nqi qis, tuaj yeem siv rau qee yam khoom siv hluav taws xob yam tsis muaj kev tiv thaiv ib puag ncig.

2, txhuas-dawb solder paste: ib puag ncig tus phooj ywg cov khoom xyaw, me ntsis kev puas tsuaj, siv nyob rau hauv ib puag ncig tus phooj ywg cov khoom siv hluav taws xob, nrog rau kev txhim kho ntawm lub teb chaws ib puag ncig yuav tsum tau, txhuas-dawb technology nyob rau hauv kev lag luam smt yuav ua ib tug qauv.

Qhov thib ob, raws li lub melting point ntawm solder paste classification

Feem ntau hais lus, lub melting point ntawm solder paste yuav muab faib ua kub, nruab nrab kub thiab tsis kub.

Feem ntau siv kub yog Sn-Ag-Cu 305,0307; Sn-Bi-Ag tau pom nyob rau hauv nruab nrab kub. Sn-Bi feem ntau yog siv rau qhov kub thiab txias. Hauv SMT thaj ua haujlwm yuav tsum tau xaiv raws li cov khoom sib txawv.

Peb, raws li qhov zoo ntawm tin hmoov faib

Raws li txoj kab uas hla ntawm cov tin hmoov, cov tin muab tshuaj txhuam tuaj yeem muab faib ua 1, 2, 3, 4, 5, 6 qib hmoov, ntawm 3, 4, 5 hmoov yog feem ntau siv. Cov khoom lag luam ntau dua, cov tin hmoov xaiv yuav tsum me dua, tab sis qhov me me ntawm cov tin hmoov, qhov sib thooj oxidation cheeb tsam ntawm cov tin hmoov yuav nce, thiab cov tin hmoov yuav pab txhim kho kev luam ntawv zoo.

No. 3 hmoov: Tus nqi kuj pheej yig, feem ntau siv hauv cov txheej txheem smt loj;

No. 4 hmoov: feem ntau siv nyob rau hauv nruj ko taw IC, smt nti ua;

No. 5 hmoov: Feem ntau siv rau hauv cov khoom siv vuam zoo heev, cov xov tooj ntawm tes, ntsiav tshuaj thiab lwm yam khoom xav tau; Qhov nyuaj dua qhov smt thaj ua cov khoom lag luam yog, qhov tseem ceeb tshaj qhov kev xaiv ntawm cov tshuaj txhuam hniav yog qhov tseem ceeb, thiab qhov kev xaiv ntawm cov khoom siv uas haum rau cov khoom pab txhim kho cov txheej txheem smt thaj ua haujlwm.