SMT vuam ua rau

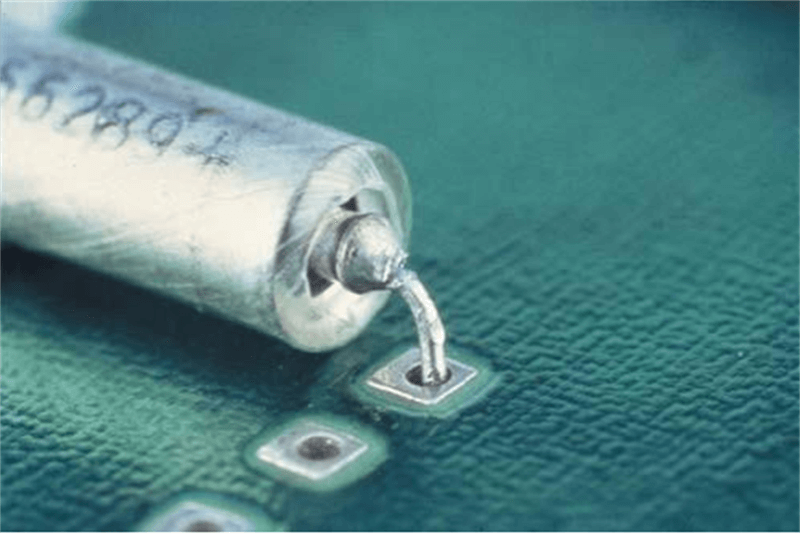

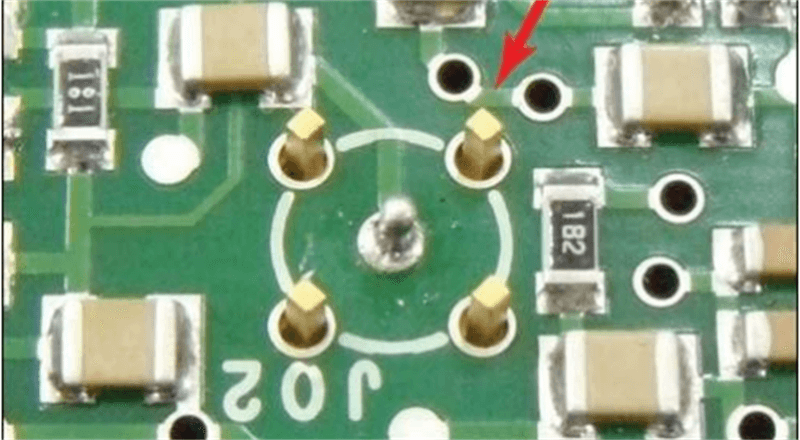

1. PCB ncoo tsim tsis xws luag

Hauv cov txheej txheem tsim ntawm qee qhov PCB, vim tias qhov chaw me me, lub qhov tsuas tuaj yeem ua si ntawm lub ncoo, tab sis cov tshuaj txhuam hniav muaj cov dej ntws tawm, uas tuaj yeem nkag mus rau hauv lub qhov, ua rau tsis muaj cov nplaum nplaum rau hauv reflow welding, yog li thaum tus pin tsis txaus noj tin, nws yuav ua rau lub vuam siv lub tshuab.

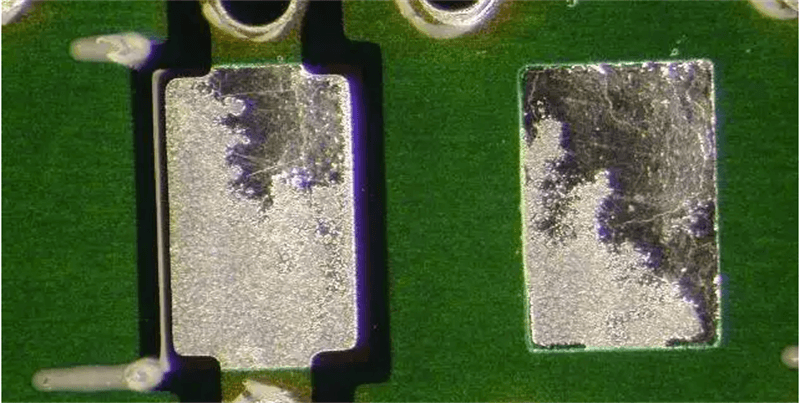

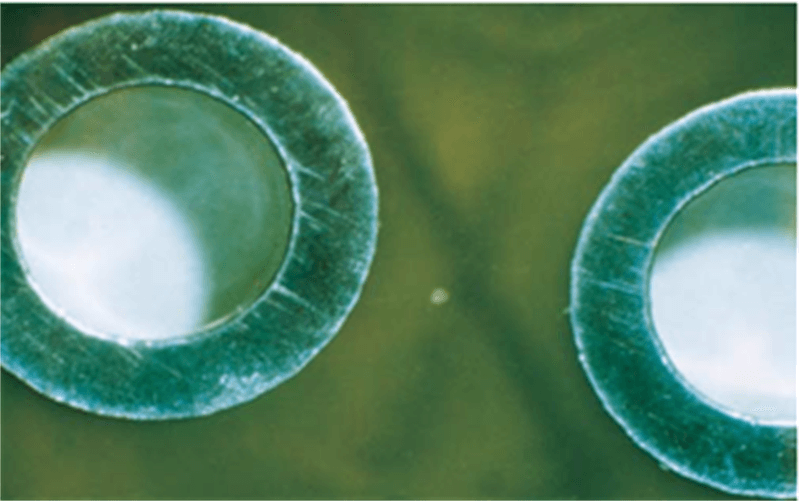

2.Pad nto oxidation

Tom qab rov tinning lub ncoo oxidized, reflow welding yuav ua rau virtual vuam, yog li thaum lub ncoo oxidizes, nws yuav tsum tau qhuav ua ntej. Yog tias oxidation hnyav heev, nws yuav tsum tau tso tseg.

3.Reflow kub los yog kub cheeb tsam lub sij hawm tsis txaus

Tom qab lub thaj ua kom tiav, qhov kub tsis txaus thaum dhau los ntawm qhov chaw reflow preheating thiab qhov chaw kub tsis tu ncua, ua rau qee qhov kub yaj nce toj tin uas tsis tau tshwm sim tom qab nkag mus rau qhov kub siab reflow cheeb tsam, ua rau tsis txaus tin noj ntawm cov khoom siv tus pin, uas ua rau lub vuam virtual.

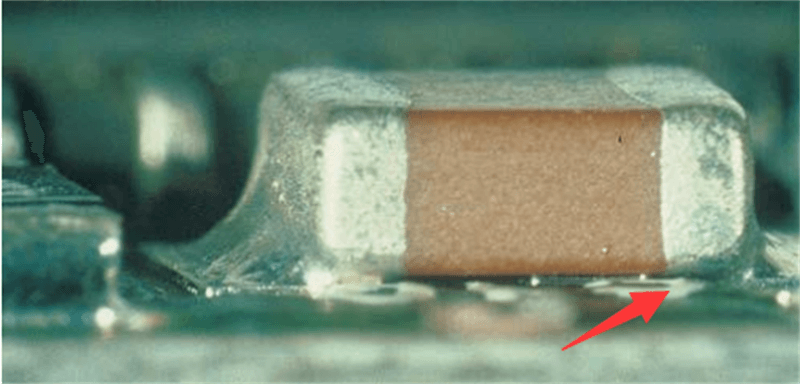

4.Solder paste luam ntawv tsawg dua

Thaum cov tshuaj txhuam hniav yog txhuam, nws yuav yog vim qhov qhib me me hauv cov hlau mesh thiab lub siab ntau dhau ntawm cov tshuab luam ntawv scraper, ua rau tsis tshua muaj vuam paste luam ntawv thiab ceev volatilization ntawm cov tshuaj txhuam rau reflow welding, ua rau cov vuam siv tshuab.

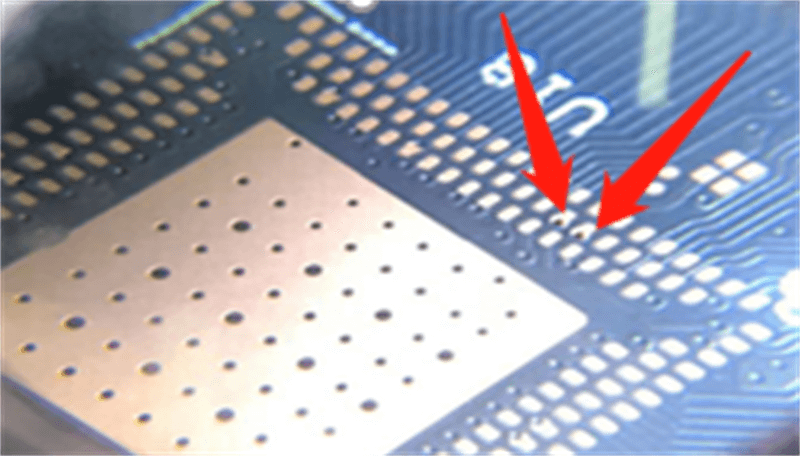

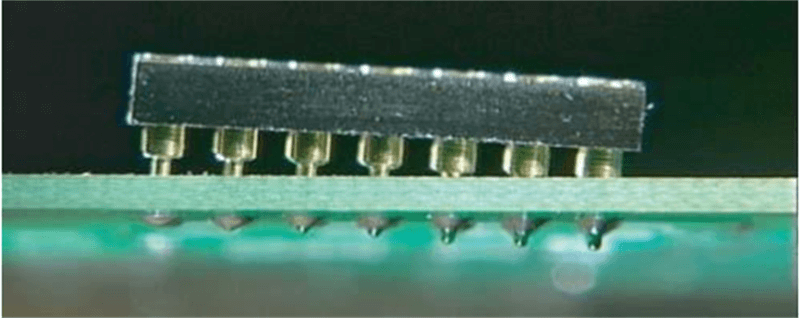

5.High-pin li

Thaum lub high-pin ntaus ntawv yog SMT, tej zaum nws yuav yog vim li cas, lub Cheebtsam yog deformed, lub PCB lub rooj tsavxwm yog khoov, los yog qhov tsis zoo siab ntawm qhov chaw tso tshuab yog tsis txaus, uas yuav ua rau sib txawv kub melting ntawm lub solder, uas ua rau lub welding virtual.

DIP virtual vuam vim li cas

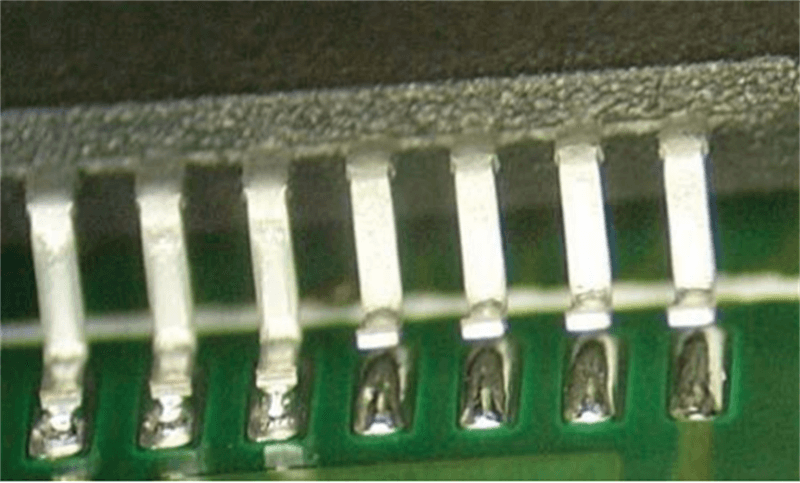

1.PCB plug-in qhov tsim tsis xws luag

PCB plug-in qhov, kam rau ua yog nyob nruab nrab ntawm ± 0.075mm, PCB ntim qhov loj dua tus pin ntawm lub cev lub cev, cov cuab yeej yuav xoob, ua rau tsis txaus tin, virtual vuam lossis cua vuam thiab lwm yam teeb meem zoo.

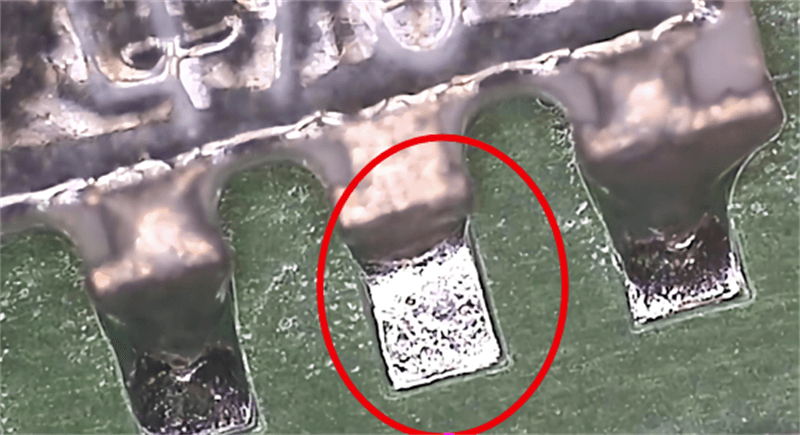

2.Pad thiab qhov oxidation

PCB pad qhov yog tsis huv, oxidized, los yog paug nrog cov khoom nyiag, roj, hws stains, thiab lwm yam, uas yuav ua rau weldability tsis zoo los yog tsis-weldability, uas ua rau lub vuam virtual thiab huab cua welding.

3.PCB pawg thawj coj saib thiab cov cuab yeej zoo

Yuav PCB boards, cov khoom siv thiab lwm yam khoom siv tsis tsim nyog, tsis muaj qhov kev lees paub nruj heev tau ua tiav, thiab muaj teeb meem zoo xws li vuam virtual thaum sib dhos.

4.PCB pawg thawj coj saib thiab cov cuab yeej siv tas sijhawm

Yuav PCB boards thiab cov khoom siv, vim tias lub sijhawm khoom xa tuaj ntev dhau lawm, cuam tshuam los ntawm cov khoom lag luam ib puag ncig, xws li kub, av noo lossis corrosive gases, uas ua rau vuam phenomena xws li virtual vuam.

5.Wave soldering khoom yam tseem ceeb

Qhov kub siab nyob rau hauv yoj vuam rauv ua rau kom nrawm oxidation ntawm cov khoom siv thiab cov khoom siv hauv paus, uas ua rau txo qhov adhesion ntawm qhov chaw rau cov khoom siv kua nplaum. Tsis tas li ntawd, qhov kub thiab txias kuj tseem ua rau lub ntsej muag ntxhib ntawm cov khoom siv hauv paus, ua rau txo qis capillary nkaus thiab tsis zoo diffusivity, uas ua rau lub vuam virtual.

Post lub sij hawm: Lub Xya hli ntuj-11-2023