PCB multilayer compaction yog txheej txheem ua ntu zus. Qhov no txhais tau hais tias lub hauv paus ntawm txheej txheej yuav yog ib daim ntawm tooj liab ntawv ci nrog ib txheej ntawm prepreg nteg rau saum. Tus naj npawb ntawm cov khaubncaws sab nraud povtseg ntawm prepreg sib txawv raws li kev ua haujlwm. Tsis tas li ntawd, cov tub ntxhais sab hauv yog muab tso rau ntawm prepreg billet txheej thiab tom qab ntawd ntxiv ntim nrog prepreg billet txheej them nrog tooj liab ntawv nyiaj. Lub laminate ntawm ntau txheej PCB yog li ua. Stack zoo tib yam laminates rau saum ib leeg. Tom qab ntawv kawg ntxiv, ib pawg zaum kawg raug tsim, hu ua "phau ntawv," thiab txhua pawg hu ua "chaw."

Thaum phau ntawv tiav lawm, nws raug xa mus rau lub tshuab hydraulic. Cov xovxwm hydraulic yog rhuab thiab siv ntau lub siab thiab lub tshuab nqus tsev rau phau ntawv. Cov txheej txheem no hu ua curing vim nws inhibits kev sib cuag ntawm cov laminates thiab ib leeg thiab tso cai rau cov resin prepreg fuse nrog cov tub ntxhais thiab ntawv ci. Tom qab ntawd cov khoom raug muab tshem tawm thiab txias ntawm chav tsev kub kom tso cai rau cov resin los kho, yog li ua kom tiav cov khoom ntawm tooj liab multilayer PCB manufacturing.

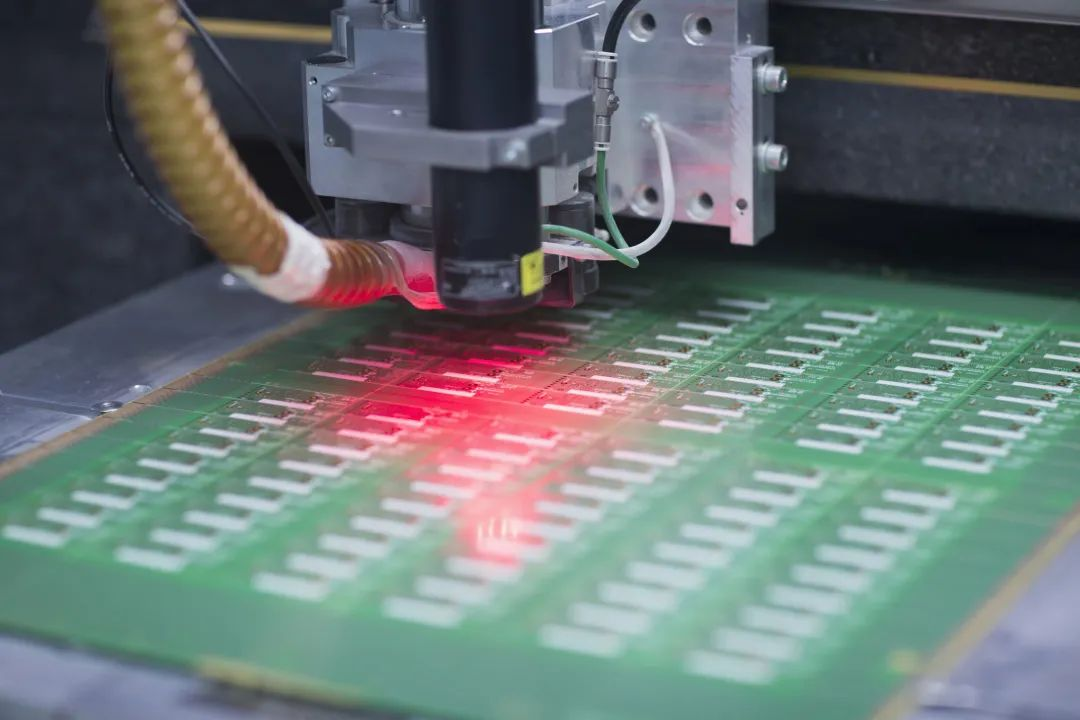

Tom qab cov ntawv sib txawv raw khoom raug txiav raws li qhov loj me, cov ntawv sib txawv raug xaiv raws li qhov tuab ntawm daim ntawv los tsim cov slab, thiab cov laminated slab tau sib sau ua ke rau hauv chav nias raws li cov txheej txheem xav tau. Thawb lub tshuab nias rau hauv lub tshuab laminating rau nias thiab sib sau.

5 theem ntawm kev tswj qhov kub thiab txias

(a) Preheating theem: qhov kub yog los ntawm chav tsev kub mus rau qhov pib kub ntawm qhov chaw kho cov tshuaj tiv thaiv, thaum lub hauv paus txheej resin yog rhuab, ib feem ntawm cov volatiles tawm, thiab lub siab yog 1/3 mus rau 1/2 ntawm tag nrho cov siab.

(b) rwb thaiv tsev theem: txheej txheej resin yog kho ntawm tus nqi qis dua. Cov tub ntxhais txheej resin yog uniformly rhuab thiab melted, thiab lub interface ntawm resin txheej pib fuse nrog ib leeg.

(c) cua sov theem: los ntawm qhov pib kub ntawm curing mus rau qhov siab tshaj plaws kub teev thaum nias, lub cua kub ceev yuav tsum tsis txhob ceev heev, txwv tsis pub lub curing ceev ntawm lub nto txheej yuav ceev heev, thiab nws yuav tsis tau zoo integrated nrog cov tub ntxhais txheej resin, uas ua rau lub stratification los yog tawg ntawm cov khoom tiav.

(d) qhov ntsuas kub tsis tu ncua: thaum qhov kub nce mus txog qhov siab tshaj plaws kom tswj tau qhov theem tsis tu ncua, lub luag haujlwm ntawm cov theem no yog los xyuas kom meej tias cov txheej txheej txheej resin tau kho kom zoo, cov tub ntxhais txheej txheej resin yog uniformly plasticized, thiab xyuas kom meej melting ua ke ntawm cov txheej txheej ntawm cov ntaub ntawv, nyob rau hauv qhov kev txiav txim ntawm lub siab kom nws ib tug uniform ntom tag nrho, thiab tom qab ntawd cov khoom tiav tiav.

(e) Txias theem: Thaum cov resin ntawm nruab nrab txheej txheej ntawm lub slab tau kho tag nrho thiab tag nrho nrog cov tub ntxhais txheej resin, nws tuaj yeem ua kom txias thiab txias, thiab txoj kev ua kom txias yog kom dhau cov dej txias hauv cov phaj kub ntawm cov xovxwm, uas tuaj yeem ua kom txias txias. Cov theem no yuav tsum tau ua nyob rau hauv kev saib xyuas ntawm lub siab uas tau teev tseg, thiab qhov tsim nyog txias yuav tsum tau tswj. Thaum lub phaj kub poob qis dua qhov ntsuas kub uas tsim nyog, lub siab tso tawm tuaj yeem ua tiav.

Post lub sij hawm: Mar-07-2024