Thaum lub sij hawm tsim cov txheej txheem ntawm PCB boards, ntau yam tsis tau npaj txhij yuav tshwm sim, xws li electroplated tooj liab, tshuaj tooj liab plating, kub plating, tin-lead alloy plating thiab lwm yam plating txheej delamination. Yog li dab tsi yog vim li cas rau qhov no stratification?

Nyob rau hauv lub irradiation ntawm ultraviolet lub teeb, lub photoinitiator uas absorbs lub teeb lub zog yog decomposed mus rau hauv lub dawb pab pawg neeg uas ua rau lub photopolymerization cov tshuaj tiv thaiv thiab tsim lub cev molecule uas yog insoluble nyob rau hauv dilute alkali tov. Nyob rau hauv qhov raug, vim tsis tiav polymerization, thaum lub sij hawm txoj kev loj hlob, cov zaj duab xis o thiab softening, ua rau cov kab tsis meej thiab txawm tias zaj duab xis ntog, ua rau tsis zoo bonding ntawm zaj duab xis thiab tooj liab; Yog tias qhov cuam tshuam ntau dhau, nws yuav ua rau muaj teeb meem hauv kev txhim kho, thiab nws tseem yuav ua rau warping thiab tev tawm thaum txheej txheem plating, tsim infiltration plating. Yog li nws yog ib qho tseem ceeb los tswj lub zog raug; Tom qab kho qhov saum npoo ntawm tooj liab, lub sij hawm tu tsis yooj yim yuav ntev dhau, vim tias cov dej ntxuav kuj muaj qee cov tshuaj acidic, txawm hais tias nws cov ntsiab lus tsis muaj zog, tab sis qhov cuam tshuam ntawm cov tooj liab tsis tuaj yeem ua rau maj mam, thiab kev ua haujlwm tu yuav tsum tau ua raws li cov txheej txheem tshwj xeeb.

Qhov laj thawj tseem ceeb yog vim li cas cov txheej kub ntog tawm ntawm cov txheej npib tsib xee yog qhov kev kho saum npoo ntawm npib tsib xee. Kev ua haujlwm tsis zoo ntawm cov nickel hlau yog qhov nyuaj kom tau txais txiaj ntsig zoo. Qhov saum npoo ntawm npib tsib xee txheej yog ib qho yooj yim los tsim cov zaj duab xis passivation nyob rau hauv cov huab cua, xws li kev kho tsis raug, nws yuav cais cov kub txheej los ntawm qhov chaw ntawm cov nickel txheej. Yog tias qhov kev ua kom tsis haum rau hauv electroplating, cov txheej kub yuav raug tshem tawm ntawm cov txheej npib tsib xee thiab tev tawm. Qhov thib ob yog vim li cas tom qab ua kom tiav, lub sij hawm tu lub sij hawm ntev dhau lawm, ua rau cov zaj duab xis passivation yuav tsum tau rov ua dua nyob rau saum npoo nickel, thiab ces yuav gilded, uas yuav inevitably tsim defects nyob rau hauv lub txheej.

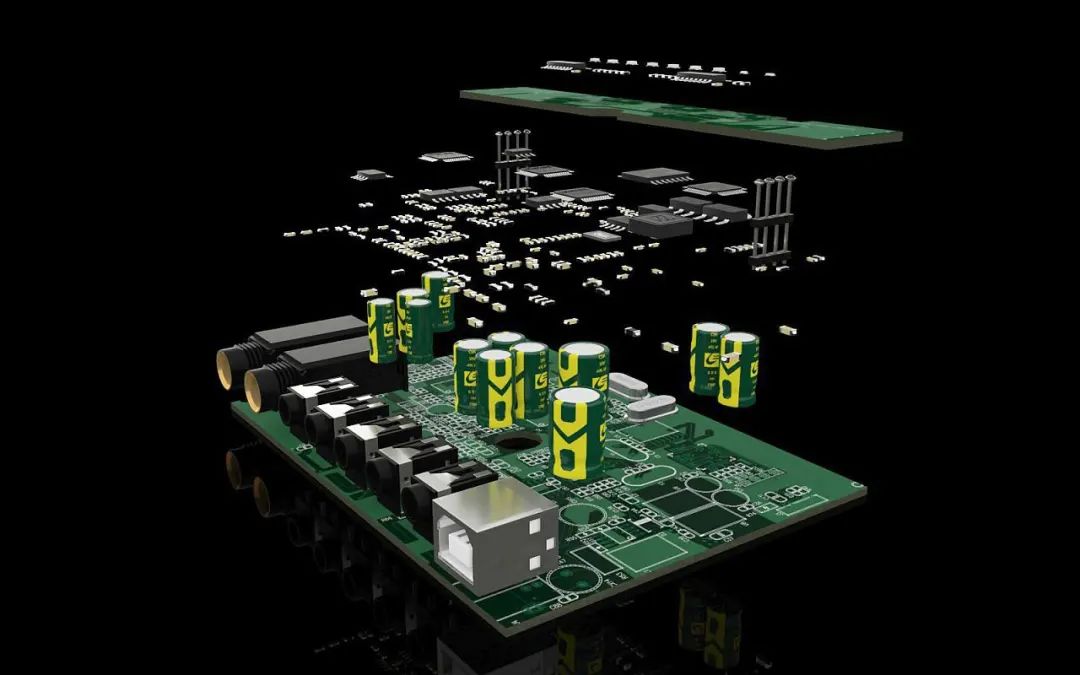

Muaj ntau qhov laj thawj rau plating delamination, yog tias koj xav ua kom muaj qhov xwm txheej zoo sib xws hauv cov txheej txheem ntawm cov phaj ntau lawm tsis tshwm sim, nws muaj kev sib raug zoo nrog kev saib xyuas thiab lub luag haujlwm ntawm cov kws tshaj lij. Yog li ntawd, cov chaw tsim khoom PCB zoo heev yuav ua cov txheej txheem kev cob qhia siab rau txhua tus neeg ua haujlwm hauv kev cob qhia txhawm rau tiv thaiv kev xa khoom tsis zoo.

Post lub sij hawm: Apr-07-2024