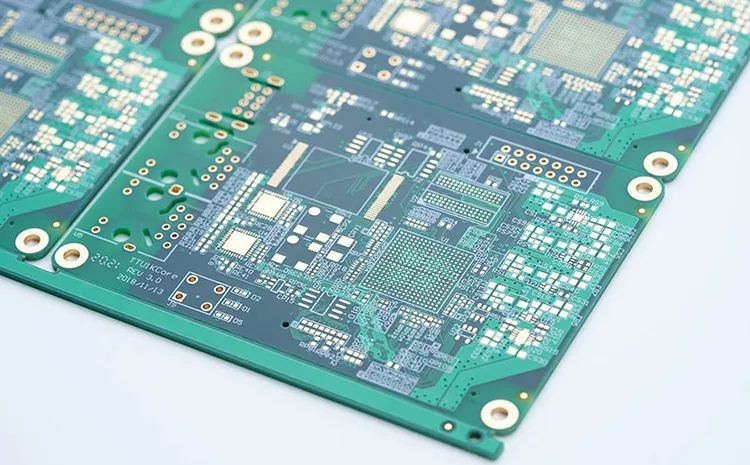

PCB vim nws qhov tseeb thiab nruj, kev noj qab haus huv ib puag ncig ntawm txhua lub rooj cob qhia PCB yog qhov siab heev, thiab qee qhov kev cob qhia tseem raug rau "lub teeb daj" txhua hnub. Cov av noo, kuj yog ib qho ntawm cov cim qhia uas yuav tsum tau tswj nruj me ntsis, hnub no peb yuav tham txog qhov cuam tshuam ntawm cov av noo ntawm PCBA.

Qhov tseem ceeb "humidity"

Humidity yog ib qho tseem ceeb heev thiab tswj nruj me ntsis hauv cov txheej txheem tsim khoom. Cov av noo tsawg tuaj yeem ua rau dryness, nce ESD, nce plua plav, yooj yim clogging ntawm template qhib, thiab nce template hnav. Kev xyaum tau ua pov thawj tias cov av qis yuav cuam tshuam ncaj qha thiab txo cov peev txheej ntau lawm. Siab dhau lawm yuav ua rau cov khoom nqus dej noo, ua rau delamination, paj kws los cuam tshuam, thiab cov khoom siv solder. Moisture kuj txo TG tus nqi ntawm cov khoom thiab ua rau kom lub zog dynamic warping thaum reflow vuam.

Taw qhia rau saum npoo av noo

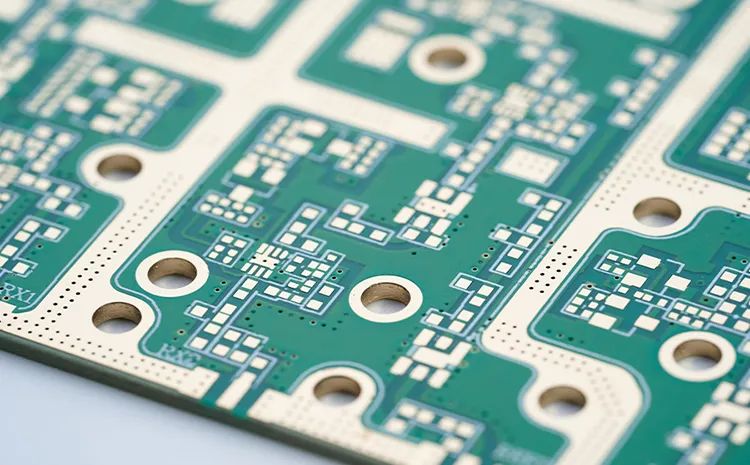

Yuav luag txhua qhov chaw ntawm cov khoom (xws li hlau, iav, ceramics, silicon, thiab lwm yam) muaj cov dej ntub dej-nqus txheej (ib zaug lossis ntau txheej molecular) uas pom tau thaum qhov kub thiab txias sib npaug ntawm cov dej lwg ntawm cov huab cua ib puag ncig (nyob ntawm qhov kub thiab txias, av noo, thiab cua siab). Kev sib txhuam ntawm cov hlau thiab hlau nce nrog qhov txo qis ntawm cov av noo, thiab cov av noo ntawm cov txheeb ze ntawm 20% RH thiab qis dua, qhov kev sib txhuam yog 1.5 npaug siab dua ntawm cov av noo ntawm 80% RH.

Porous los yog noo noo absorbing nto (epoxy resins, plastics, fluxes, thiab lwm yam) nyiam nqus cov khaubncaws sab nraud povtseg, thiab txawm tias thaum qhov kub thiab txias ntawm qhov dew point (condensation), lub absorbent txheej uas muaj dej tsis pom nyob rau saum npoo ntawm cov khoom.

Nws yog cov dej nyob rau hauv ib leeg-molecule absorbent khaubncaws sab nraud povtseg ntawm cov nto uas permeates mus rau hauv lub yas encapsulation ntaus ntawv (MSD), thiab thaum ib leeg-molecule absorbent khaubncaws sab nraud povtseg mus txog 20 khaubncaws sab nraud povtseg nyob rau hauv tuab, cov ya raws absorbed los ntawm ib leeg-molecule absorbent txheej thaum kawg ua rau paj kws cov nyhuv thaum reflow soldering.

Kev cuam tshuam ntawm cov av noo thaum tsim khoom

Cov av noo muaj ntau yam cuam tshuam rau kev tsim khoom thiab kev tsim khoom. Feem ntau, cov av noo tsis pom (tshwj tsis yog qhov hnyav ntxiv), tab sis qhov tshwm sim yog qhov pores, voids, solder spatter, solder balls, thiab hauv qab-sau voids.

Nyob rau hauv txhua txoj kev, kev tswj cov av noo thiab av noo yog ib qho tseem ceeb heev, yog tias cov tsos ntawm lub cev nto yog txawv txav, cov khoom tiav tsis tsim nyog. Yog li ntawd, lub rooj cob qhia ib txwm ua haujlwm yuav tsum xyuas kom meej tias cov dej noo thiab cov av noo ntawm lub substrate nto raug tswj kom zoo los xyuas kom meej tias cov ntsuas ib puag ncig hauv cov txheej txheem ntawm cov khoom tiav yog nyob rau hauv qhov kev teev tseg.

Post lub sij hawm: Mar-26-2024