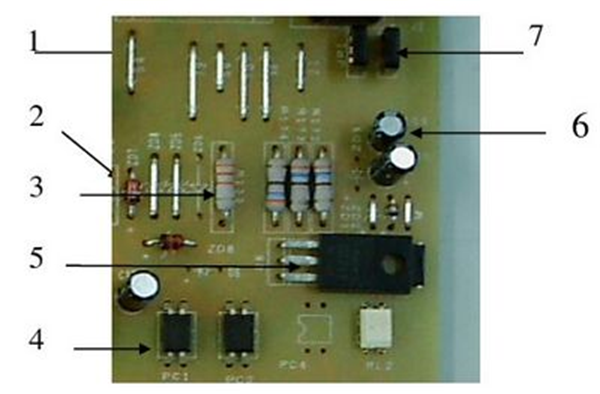

Cov txheej txheem PCBA ntxaws ntxaws (nrog rau tag nrho cov txheej txheem ntawm DIP), tuaj rau hauv thiab pom!

"Wave Soldering txheej txheem"

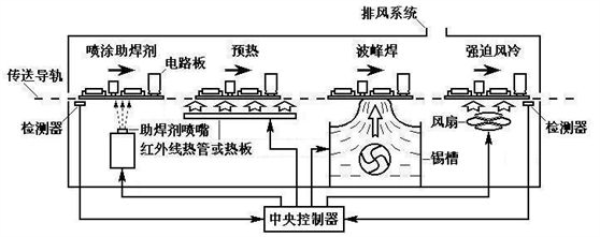

Wave soldering feem ntau yog txheej txheem vuam rau cov khoom siv plug-in. Nws yog ib qho txheej txheem uas cov kua nplaum nplaum, nrog kev pab los ntawm lub twj tso kua mis, tsim ib qho tshwj xeeb zoo ntawm cov yoj yoj ntawm cov kua dej ntawm lub tank solder, thiab PCB ntawm cov khoom sib txuas tau dhau los ntawm cov yoj yoj lub ncov ntawm ib lub kaum ntse ntse thiab qhov tob tob ntawm cov saw hlau sib txuas kom ua tiav cov vuam sib txuas, raws li qhia hauv daim duab hauv qab no.

Cov txheej txheem dav dav yog raws li hauv qab no: ntaus ntawv ntxig - PCB thauj khoom - yoj soldering - PCB unloading - DIP tus pin trimming - tu, raws li qhia hauv daim duab hauv qab no.

1.THC insertion technology

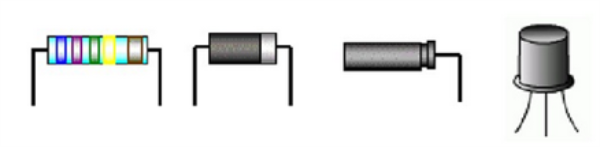

1. Cov khoom siv tus pin sib sau

DIP cov cuab yeej yuav tsum tau ua kom zoo li qub ua ntej tso

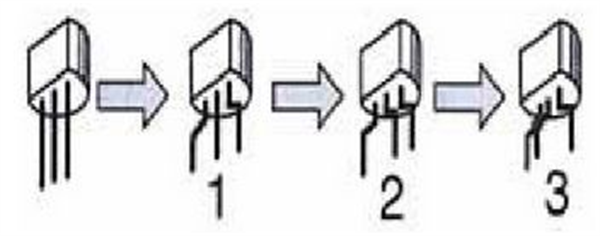

(1) Cov khoom siv tes ua tiav shaping: tus pin khoov tuaj yeem ua tau zoo li tus tweezers los yog ib lub taub hau me me, raws li qhia hauv daim duab hauv qab no.

(2) Lub tshuab ua haujlwm ntawm cov khoom sib txuas: lub tshuab shaping ntawm cov khoom tiav nrog lub tshuab tshwj xeeb shaping, nws txoj hauv kev ua haujlwm yog tias lub feeder siv vibration feeding rau cov khoom noj, (xws li plug-in transistor) nrog lub divider los nrhiav cov transistor, thawj kauj ruam yog khoov tus pins ntawm ob sab ntawm sab laug thiab sab xis; Qhov thib ob kauj ruam yog khoov tus pin nruab nrab rov qab los yog rau pem hauv ntej rau daim ntawv. Raws li pom hauv daim duab hauv qab no.

2. Ntxig cov khoom

Los ntawm qhov kev siv thev naus laus zis tau muab faib ua phau ntawv ntxig thiab cov cuab yeej siv tshuab tsis siv neeg nkag

(1) Kev tuav tuav thiab vuam yuav tsum xub ntxig rau cov khoom uas yuav tsum tau kho, xws li cov khib nyiab txias, bracket, clip, thiab lwm yam, ntawm lub hwj chim ntaus ntawv, thiab tom qab ntawd ntxig cov khoom uas yuav tsum tau welded thiab kho. Tsis txhob kov cov pins tivthaiv thiab tooj liab ntawv ntawm lub phaj luam ntawv ncaj qha thaum ntxig.

(2) Mechanical automatic plug-in (hu ua AI) yog cov khoom siv hluav taws xob zoo tshaj plaws hauv kev teeb tsa cov khoom siv hluav taws xob niaj hnub. Kev teeb tsa ntawm cov cuab yeej siv tshuab tsis siv neeg yuav tsum xub ntxig cov khoom siv nrog qhov siab qis, thiab tom qab ntawd nruab cov khoom siv nrog qhov siab dua. Cov khoom tseem ceeb tseem ceeb yuav tsum tau muab tso rau hauv qhov kawg installation. Lub installation ntawm tshav kub dissipation khib, bracket, clip, thiab lwm yam yuav tsum nyob ze rau cov txheej txheem vuam. Kev sib dhos ua ntu zus ntawm PCB cov khoom yog qhia hauv daim duab hauv qab no.

3. Wave soldering

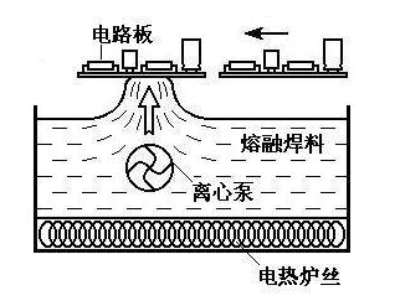

(1) Lub hauv paus ntsiab lus ua haujlwm ntawm yoj soldering

Wave soldering yog ib hom kev siv thev naus laus zis uas tsim cov duab tshwj xeeb ntawm cov yoj yoj rau ntawm qhov chaw ntawm cov kua nplaum uas siv los ntawm kev siv lub siab, thiab ua ib qho chaw nyob rau hauv qhov chaw sib txuas ntawm tus pin vuam thaum cov khoom sib dhos nrog cov khoom siv dhau los ntawm cov yoj yoj ntawm lub kaum sab xis. Cov tivthaiv yog thawj zaug preheated nyob rau hauv lub vuam tshuab preheating cheeb tsam thaum lub sij hawm tus txheej txheem ntawm kis tau tus mob los ntawm cov saw conveyor (cov tivthaiv preheating thiab qhov kub thiab txias yuav tsum tau tseem tswj los ntawm lub predetermined kub nkhaus). Nyob rau hauv qhov tseeb welding, nws yog feem ntau yuav tsum tau tswj lub preheating qhov chaw ntawm lub Cheebtsam ntawm lub Cheebtsam, yog li muaj ntau yam khoom siv tau ntxiv cov khoom siv ntsuas kub (xws li infrared detectors). Tom qab preheating, lub rooj sib txoos nkag mus rau hauv cov hlau groove rau vuam. Lub tin tank muaj molten kua solder, thiab lub nozzle nyob rau hauv qab ntawm lub steel tank sprays ib tug ruaj yoj yoj crest ntawm lub molten solder, yog li ntawd thaum lub vuam nto ntawm lub Cheebtsam kis los ntawm lub yoj, nws yog rhuab los ntawm solder yoj, thiab solder yoj kuj moistens lub vuam cheeb tsam thiab nthuav mus sau, thaum kawg ua tiav cov txheej txheem vuam. Nws txoj haujlwm ua haujlwm yog qhia hauv daim duab hauv qab no.

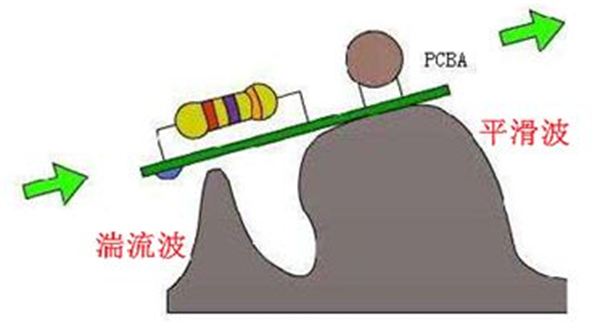

Wave soldering siv convection tshav kub hloov txoj hauv kev los ua kom sov qhov chaw vuam. Lub molten solder yoj ua raws li qhov chaw tshav kub, ntawm ib sab tes ntws los ntxuav tus pin vuam cheeb tsam, ntawm qhov tod tes kuj plays lub luag hauj lwm kub conduction, thiab tus pin vuam cheeb tsam yog rhuab nyob rau hauv qhov kev txiav txim. Txhawm rau kom ntseeg tau tias qhov chaw vuam cua sov, qhov vuam nthwv dej feem ntau muaj qhov dav, yog li ntawd thaum lub vuam nto ntawm cov khoom dhau los ntawm yoj, muaj cua sov txaus, ntub dej, thiab lwm yam. Nyob rau hauv ib txwm yoj soldering, ib nthwv dej feem ntau yog siv, thiab cov nthwv dej zoo sib xws. Nrog kev siv cov hlau lead, nws yog tam sim no saws nyob rau hauv daim ntawv ntawm ob yoj. Raws li pom hauv daim duab hauv qab no.

Tus pin ntawm cov tivthaiv muab ib txoj hauv kev rau lub solder mus rau hauv lub metallized los ntawm lub qhov nyob rau hauv lub xeev khoom. Thaum tus pin kov cov yoj yoj, cov kua nplaum nce mus rau tus pin thiab lub qhov phab ntsa los ntawm txoj kev nro saum npoo. Qhov kev txiav txim ntawm capillary ntawm metallized los ntawm qhov zoo txhim kho txoj kev nce toj. Tom qab lub solder ncav cuag PcB ncoo, nws kis tawm nyob rau hauv qhov kev txiav txim ntawm qhov nro ntawm lub ncoo. Lub nce solder drains cov roj flux thiab huab cua los ntawm lub qhov, yog li sau lub qhov los ntawm lub qhov thiab tsim cov solder sib koom tom qab txias.

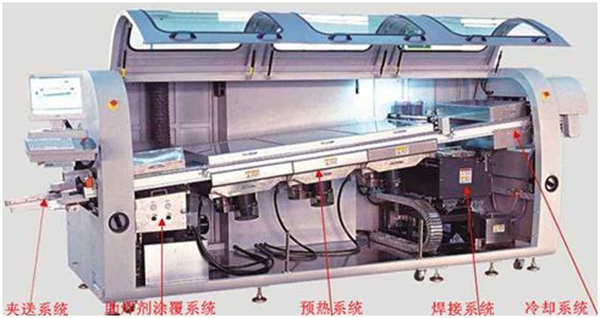

(2) Cov khoom tseem ceeb ntawm cov yoj vuam tshuab

Lub tshuab yoj vuam yog tsim los ntawm txoj siv conveyor, lub rhaub, lub tank, lub twj tso kua mis, thiab cov khoom siv flux foaming (los yog tshuaj tsuag). Nws yog tsuas yog muab faib ua flux ntxiv zone, preheating zone, vuam cheeb tsam thiab cua txias, raws li qhia nyob rau hauv daim duab hauv qab no.

3. Qhov sib txawv tseem ceeb ntawm yoj soldering thiab reflow vuam

Qhov sib txawv tseem ceeb ntawm yoj soldering thiab reflow welding yog tias cov cua sov qhov chaw thiab cov khoom siv hauv cov vuam sib txawv. Nyob rau hauv yoj soldering, lub solder yog pre-rhuab thiab melted nyob rau hauv lub tank, thiab solder yoj ua los ntawm lub twj tso kua mis plays ob lub luag hauj lwm ntawm tshav kub qhov chaw thiab solder mov. Lub molten solder yoj cua sov los ntawm lub qhov, cov ntaub qhwv, thiab cov khoom sib txuas ntawm PCB, thaum tseem muab cov solder xav tau los tsim cov pob qij txha. Nyob rau hauv reflow soldering, lub solder (solder paste) yog pre-txiav mus rau lub vuam cheeb tsam ntawm lub PCB, thiab lub luag hauj lwm ntawm lub tshav kub qhov chaw thaum lub sij hawm reflow yog re-melt lub solder.

(1) 3 Taw qhia txog kev xaiv yoj vuam txheej txheem

Wave soldering cov cuab yeej tau tsim los rau ntau tshaj 50 xyoo, thiab muaj qhov zoo ntawm kev ua haujlwm siab thiab cov khoom siv loj hauv kev tsim cov khoom siv los ntawm lub qhov thiab cov rooj sib tham hauv Circuit Court, yog li nws yog ib qho tseem ceeb tshaj plaws vuam cov cuab yeej hauv cov khoom siv hluav taws xob ntau lawm. Txawm li cas los xij, muaj qee qhov kev txwv hauv nws daim ntawv thov: (1) cov vuam tsis sib txawv.

Qhov sib txawv ntawm cov pob qij txha sib txawv ntawm tib lub rooj sib tham yuav xav tau qhov sib txawv ntawm qhov sib txawv vim lawv cov yam ntxwv sib txawv (xws li lub peev xwm kub, qhov sib txawv ntawm tus pin, qhov yuav tsum tau nkag mus rau tin, thiab lwm yam). Txawm li cas los xij, tus yam ntxwv ntawm yoj soldering yog ua kom tiav cov vuam ntawm tag nrho cov pob qij txha ntawm tag nrho cov khoom siv hluav taws xob nyob rau hauv cov txheej txheem tib yam, yog li cov khoom siv sib txawv yuav tsum tau "tso" ib leeg, uas ua rau yoj soldering nyuaj dua kom ua tau raws li cov kev xav tau ntawm cov khoom siv hluav taws xob zoo;

(2) Cov nqi khiav haujlwm siab.

Nyob rau hauv daim ntawv thov ntawm ib txwm yoj soldering, tag nrho cov phaj txau ntawm flux thiab tiam ntawm tin slag coj cov nqi khiav hauj lwm siab. Tshwj xeeb tshaj yog thaum welding tsis muaj hlau lead, vim hais tias tus nqi ntawm cov hlau lead-dawb solder yog ntau tshaj 3 npaug ntawm cov hlau lead solder, qhov nce ntawm cov nqi khiav hauj lwm tshwm sim los ntawm tin slag yog qhov xav tsis thoob. Tsis tas li ntawd, cov hlau lead-dawb txuas ntxiv yaj cov tooj liab ntawm lub ncoo, thiab cov khoom siv ntawm cov khoom siv hauv cov tin lub tog raj kheej yuav hloov mus rau lub sijhawm, uas yuav tsum tau ua kom tsis tu ncua ntawm cov ntshiab tin thiab cov nyiaj kim los daws;

(3) Kev tu thiab tu teeb meem.

Qhov seem tshuav nyob rau hauv kev tsim khoom yuav nyob twj ywm hauv kev sib kis ntawm yoj soldering, thiab cov tin slag generated yuav tsum tau muab tshem tawm tsis tu ncua, uas coj cov khoom siv nyuaj thiab kev tu xyuas ua haujlwm rau tus neeg siv; Vim li no, xaiv yoj soldering tau los ua.

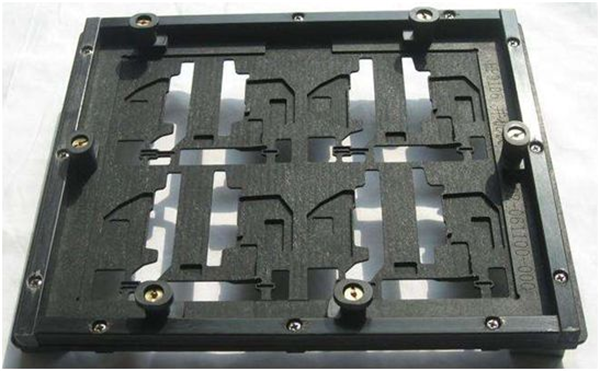

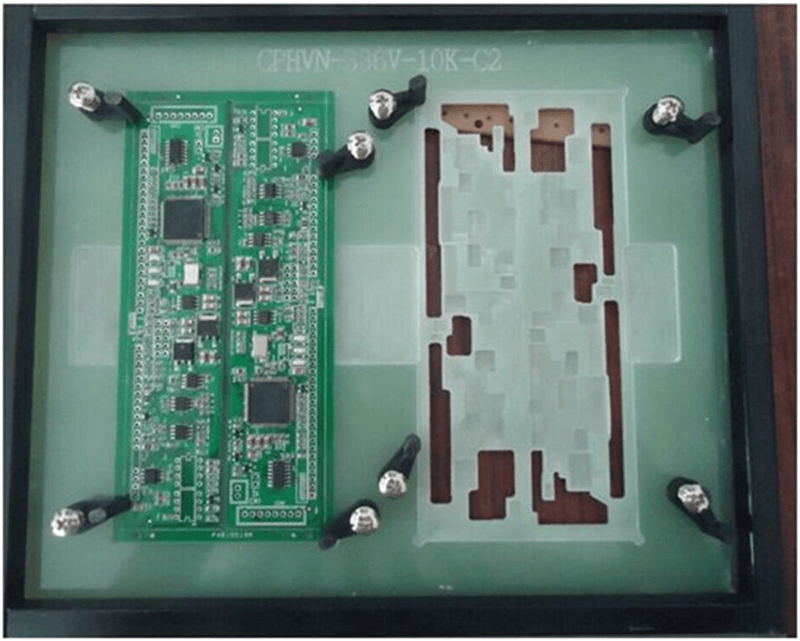

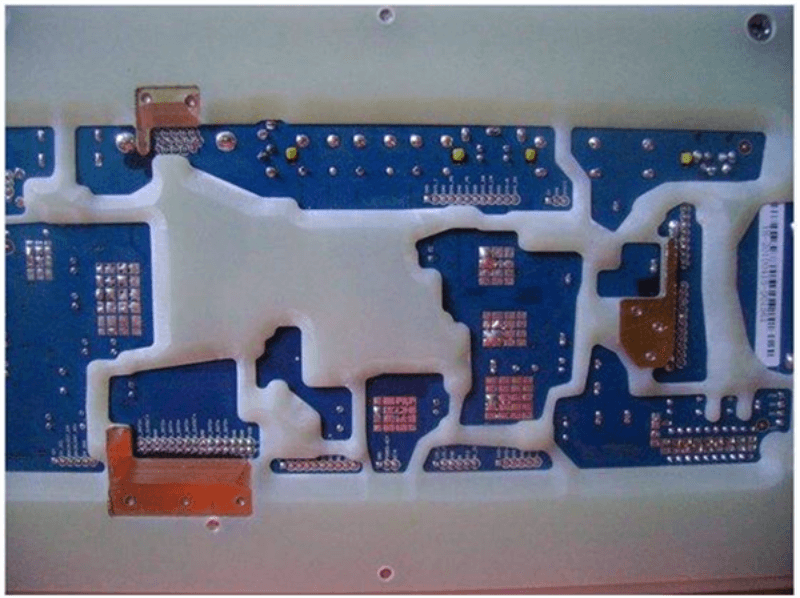

Lub npe hu ua PCBA xaiv yoj siv lub tshuab hluav taws xob tseem siv lub qhov cub qub, tab sis qhov sib txawv yog tias lub rooj tsavxwm yuav tsum tau muab tso rau hauv lub tshuab hluav taws xob tin, uas yog qhov peb feem ntau hais txog lub tshuab hluav taws xob, raws li pom hauv daim duab hauv qab no.

Cov khoom uas yuav tsum tau yoj soldering yog ces raug rau lub tin, thiab lwm qhov chaw yog tiv thaiv nrog lub tsheb cladding, raws li qhia hauv qab no. Qhov no yog me ntsis zoo li muab lub neej tso rau hauv lub pas dej da dej, qhov chaw npog los ntawm lub neej buoy yuav tsis tau dej, thiab hloov nrog lub qhov cub tin, qhov chaw npog los ntawm lub tsheb yuav tsis tau tin, thiab yuav tsis muaj teeb meem ntawm cov tin rov qab los yog qhov chaw poob.

"Los ntawm qhov reflow Vuam txheej txheem"

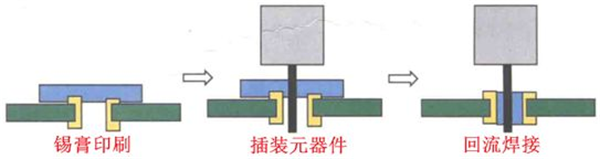

Los ntawm-qhov reflow welding yog cov txheej txheem reflow vuam rau kev ntxig cov khoom, uas yog siv rau hauv kev tsim cov phaj sib dhos uas muaj ob peb plug-ins. Lub hauv paus ntawm cov thev naus laus zis yog kev siv cov txheej txheem ntawm solder paste.

1. Kev taw qhia txog txheej txheem

Raws li daim ntawv thov txheej txheem ntawm solder paste, los ntawm lub qhov reflow vuam yuav muab faib ua peb hom: yeeb nkab luam ntawv los ntawm lub qhov reflow vuam txheej txheem, solder paste printing los ntawm lub qhov reflow vuam txheej txheem thiab molded tin ntawv los ntawm lub qhov reflow vuam txheej txheem.

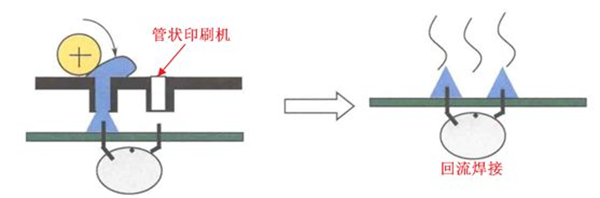

1) Tubular luam ntawv los ntawm lub qhov reflow vuam txheej txheem

Tubular luam ntawv los ntawm lub qhov reflow vuam txheej txheem yog qhov ntxov tshaj daim ntawv thov ntawm los ntawm lub qhov khoom reflow vuam txheej txheem, uas yog tsuas yog siv nyob rau hauv lub tsim ntawm cov xim TV tuner. Lub hauv paus ntawm cov txheej txheem yog solder paste tubular xovxwm, cov txheej txheem yog qhia nyob rau hauv daim duab hauv qab no.

2) Solder paste luam ntawv los ntawm lub qhov reflow vuam txheej txheem

Solder paste luam tawm los ntawm lub qhov reflow vuam txheej txheem yog tam sim no feem ntau dav siv los ntawm lub qhov reflow vuam txheej txheem, feem ntau yog siv rau sib xyaw PCBA uas muaj ib tug me me plug-ins, cov txheej txheem yog tag nrho sib xws nrog cov pa reflow welding txheej txheem, tsis muaj cov txheej txheem tshwj xeeb yuav tsum tau, qhov yuav tsum tau tsuas yog hais tias lub welded plug-nyob rau hauv Cheebtsam yuav tsum tsim nyog rau welded nyob rau hauv cov nram qab no daim duab reflow.

3) Molding tin ntawv los ntawm lub qhov reflow vuam txheej txheem

Moulded tin ntawv los ntawm lub qhov reflow vuam txheej txheem yog tsuas yog siv rau ntau tus pin connectors, solder tsis solder paste tab sis molded tin ntawv, feem ntau los ntawm cov connector chaw tsim tshuaj paus ncaj qha ntxiv, sib dhos tsuas yog yuav tsum tau rhuab.

Los ntawm qhov reflow tsim cov cai

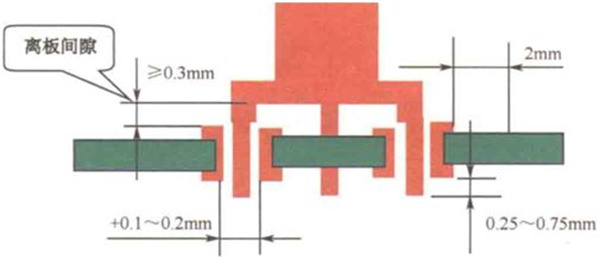

1.PCB tsim cov cai

(1) Haum rau PCB thickness tsawg dua los yog sib npaug rau 1.6mm board.

(2) Qhov dav tsawg kawg nkaus ntawm lub ncoo yog 0.25mm, thiab cov molten solder paste yog "rub" ib zaug, thiab cov hlaws tin tsis tsim.

(3) Qhov sib txawv ntawm qhov sib txawv (Sand-off) yuav tsum siab tshaj 0.3mm

(4) Qhov tsim nyog ntev ntawm cov hlau lead tawm ntawm lub ncoo yog 0.25 ~ 0.75mm.

(5) Qhov kev ncua deb tsawg kawg nkaus ntawm qhov sib nrug zoo xws li 0603 thiab lub ncoo yog 2 hli.

(6) Qhov siab tshaj plaws qhib ntawm cov hlau mesh tuaj yeem nthuav dav los ntawm 1.5mm.

(7) Lub aperture yog cov txhuas txoj kab uas hla ntxiv 0.1 ~ 0.2mm. Raws li pom hauv daim duab hauv qab no.

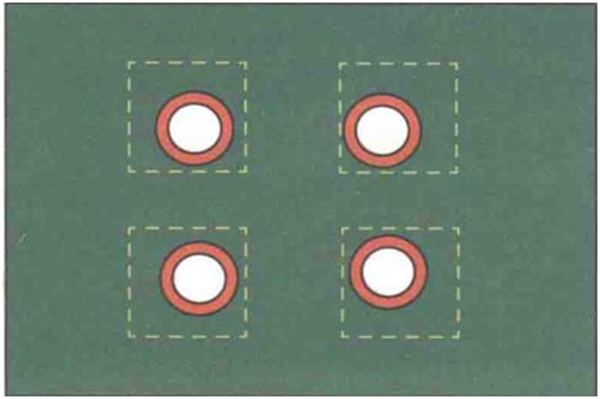

"Steel mesh qhov rais qhib qhov yuav tsum tau ua"

Feem ntau, txhawm rau ua kom tiav 50% lub qhov txhaws, lub qhov rais steel mesh yuav tsum tau nthuav dav, qhov tshwj xeeb ntawm kev nthuav dav sab nraud yuav tsum tau txiav txim siab raws li PCB thickness, lub thickness ntawm cov hlau mesh, qhov sib txawv ntawm lub qhov thiab cov hlau lead thiab lwm yam.

Feem ntau, ntev li ntev tau qhov kev nthuav dav tsis pub dhau 2 hli, cov tshuaj nplaum yuav raug rub rov qab thiab ntim rau hauv lub qhov. Nws yuav tsum raug sau tseg tias kev nthuav dav sab nraud tsis tuaj yeem raug compressed los ntawm cov khoom siv pob, lossis yuav tsum zam lub pob lub cev ntawm cov khoom tivthaiv, thiab tsim cov hlaws dai ntawm ib sab, raws li qhia hauv daim duab hauv qab no.

"Introduction to the pa Assembly Process of PCBA"

1) Ib sab mounting

Cov txheej txheem ntws tau qhia hauv daim duab hauv qab no

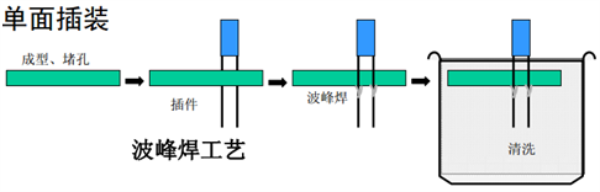

2) Ib sab ntxig

Cov txheej txheem ntws tau qhia hauv daim duab 5 hauv qab no

Kev tsim cov pins ntawm cov cuab yeej hauv nthwv dej yog ib qho ntawm qhov ua tau zoo tshaj plaws ntawm cov txheej txheem tsim khoom, uas ua rau muaj kev pheej hmoo ntawm electrostatic kev puas tsuaj thiab ua rau lub sijhawm xa khoom, thiab tseem ua rau muaj kev ua yuam kev.

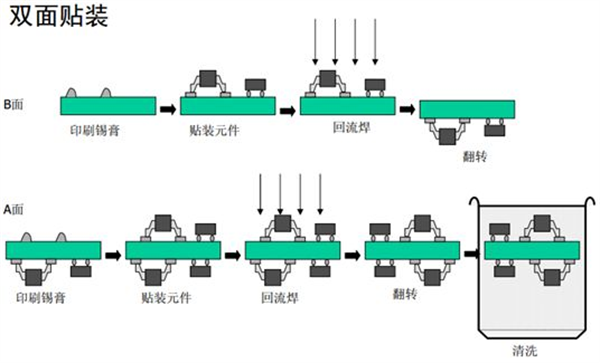

3) Ob sab mounting

Cov txheej txheem ntws tau qhia hauv daim duab hauv qab no

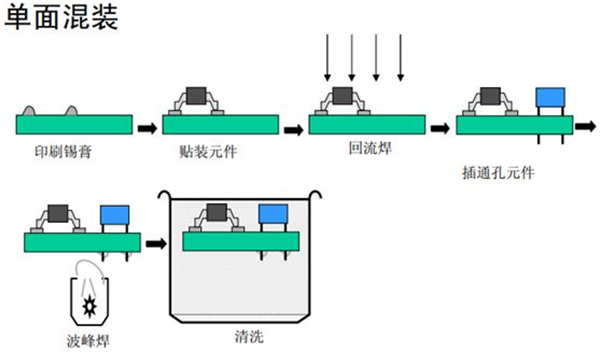

4) Ib sab sib xyaw

Cov txheej txheem ntws tau qhia hauv daim duab hauv qab no

Yog hais tias muaj ob peb yam ntawm lub qhov, reflow vuam thiab phau ntawv vuam siv tau.

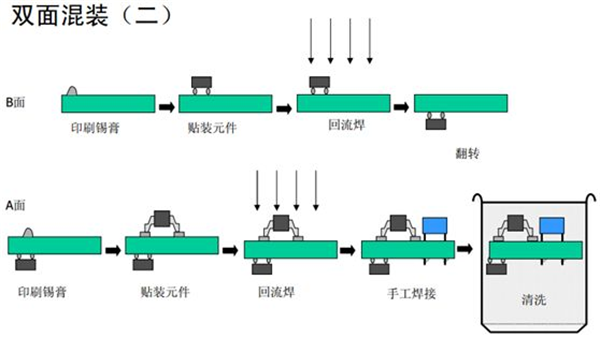

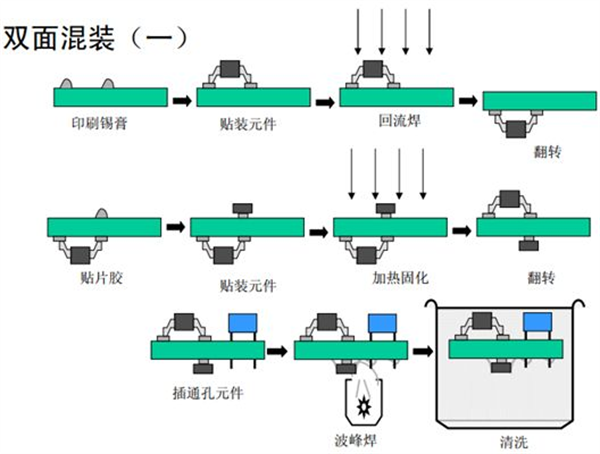

5) Kev sib xyaw ua ke ob sab

Cov txheej txheem ntws tau qhia hauv daim duab hauv qab no

Yog tias muaj ntau dua ob sab SMD cov khoom siv thiab ob peb THT cov khoom, cov khoom siv ntsaws ntsaws tuaj yeem rov ua dua lossis phau ntawv vuam. Cov txheej txheem flow chart yog qhia hauv qab no.